SPECIFICATIONS

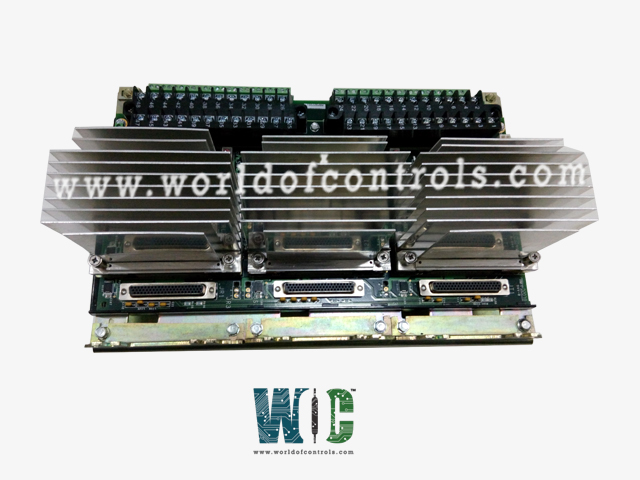

Part Number: IS230TSVBH3A

Manufacturer: General Electric

Series: Mark VIe

Function: Vibration Input Assembly

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

IS230TSVBH3A is a Vibration Input Assembly manufactured by General Electric. It facilitates precise control of valve positions using Linear Variable Differential Transformers (LVDTs). These devices ensure accurate measurement of valve positions, crucial for maintaining optimal flow and pressure in steam and fuel systems within industrial processes. Designed specifically for compatibility with the I/O pack and the WSVO servo driver, tailored to integrate seamlessly with these components.

Features

- Simplex Control: Operates with single-channel control, suitable for applications where redundancy is not a primary requirement.

- Dual Redundant Control: Provides redundancy by duplicating critical components, ensuring continuous operation even if one channel fails.

- Triple Modular Redundant (TMR) Control: Offers the highest level of redundancy with three independent channels. This configuration ensures uninterrupted operation and enhances system reliability in critical applications.

- Power Supply: Three 28 V DC power supplies are routed through plug J28 into the TSVC. This setup ensures sufficient power delivery to operate the servo valves and LVDTs reliably, supporting continuous and precise control of valve positions.

- External Trip Capability: Plugs JD1 or JD2 are designated for external trip connections originating from the protection module. These connections allow for immediate shutdown or trip commands triggered by protective system signals. This feature enhances system safety by facilitating rapid responses to critical conditions or emergencies.

Installation Procedure

- To begin installation, sensors and electro-hydraulic servo valves are connected directly to two I/O terminal blocks on the board. Each terminal block is secured with two screws and designed to accommodate up to 12 AWG wiring. This direct wiring setup facilitates the transmission of control signals and power between the TSVC and the servo valves, ensuring accurate and responsive operation in controlling steam and fuel valves.

- Adjacent to each terminal block, a shield terminal strip is mounted and connected to the chassis ground. This grounding arrangement plays a critical role in minimizing electromagnetic interference (EMI), thereby preserving signal integrity and ensuring precise measurements from the LVDTs that monitor valve positions. Proper grounding enhances the overall reliability and performance of the servo control system.

- External trip wiring from the protection module is connected to designated plugs JD1 or JD2. These connections are essential for enabling quick response actions, such as emergency shutdowns or protective trips, triggered by signals from the protection system. This feature enhances system safety by promptly addressing critical conditions to prevent equipment damage or operational risks.

- Servo Configuration: Each servo output can be configured with three coils in TMR mode, ensuring continuous operation even in the event of a single coil failure.

Jumper Selection: Jumper settings JP1, JP3, and JP5 are used to select the current levels for Servo 1, while JP2, JP4, and JP6 are used for Servo 2. These jumpers enable operators to set the appropriate current levels based on operational requirements and specifications, optimizing the performance and longevity of the electro-hydraulic servo valves.

WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs contact us.

FREQUENTLY ASKED QUESTIONS

What is IS230TSVBH3A?

It is a Vibration Input Assembly manufactured and designed by General Electric

What are the key features of the Mark VIe system?

The systems provide flexibility, integrated power supplies, connectivity with basic process control systems, and cost efficiency. They also offer a common configuration capability for streamlined setup and maintenance.

How does the system enhance safety procedures?

The systems enhance safety by providing reliable control, scalability, and customization to meet specific safety requirements, thus minimizing risks in industrial processes.