World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS230TREAH4A - Aeroderivative Turbine Emergency Trip Terminal Board is available in stock which ships the same day.

IS230TREAH4A - Aeroderivative Turbine Emergency Trip Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230TREAH4A - Aeroderivative Turbine Emergency Trip Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

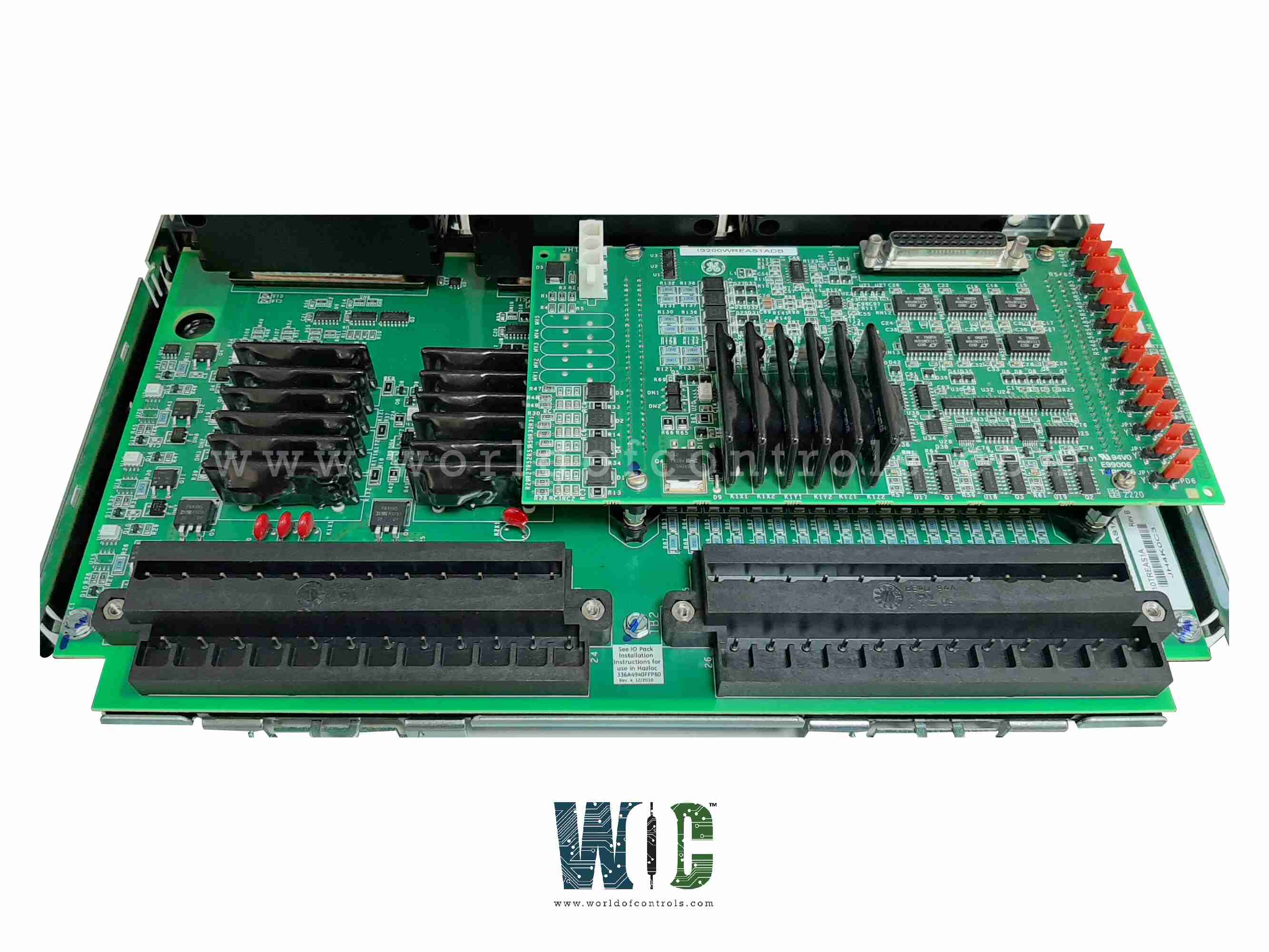

Part Number: IS230TREAH4A

Manufacturer: General Electric

Series: Mark VIe

Function: Aeroderivative Turbine Emergency Trip terminal board

Number of Inputs: 3

Number of Outputs: 2

Temperature: -30 to 65°C

MPU pulse rate range: 2 Hz to 20 kHz

MPU pulse rate accuracy: 0.05%

Number of outputs: 2 trip contacts

MPU input circuit sensitivity: 27 mV pk

Availability: In Stock

Size: 33.0 cm x 17.8 cm

Technology: Surface mount

Country of Manufacture: United States (USA)

FUNCTIONAL DESCRIPTION:

IS230TREAH4A is an Aeroderivative Turbine Emergency Trip Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The Aeroderivative Turbine Emergency Trip (TREA) terminal board works with PPRO and YPRO turbine I/O packs as part of the Mark VIe or Mark VIeS system, respectively. The inputs and outputs are as follows:

INSTALLATION:

For H1 / S1 and H2 / S2 board variants, voltage detection and the breaker relay are wired to the I/O terminal blocks TB1. Passive pulse rate pickups are wired to TB2. Each block is held down with two screws and has 24 terminals accepting up to #12 AWG wires. A shield termination strip attached to the chassis ground is located immediately to the left of each terminal block. For H3 / S3 and H4 / S4 board variants, voltage detection and the breaker relay are wired to the I/O box terminals at the top of the board. Passive pulse rate pickups are wired to the lower terminals. All terminals plug into a header on the TREA board and accept up to a single #12 AWG wire.

CONFIGURATION:

Jumpers JP1 and JP2 select the fanning of the 3 X section passive speed pickups to the S and T section PPROs or YPROs. Place the jumper over the pin pairs if you want to fan the 3 R speed input to the other two TMR sections.

WOC maintains the largest inventory of Replacement Parts for GE Distributed Turbine Control Systems. Additionally, we offer warranty-backed unused and rebuilt boards, as well as board repairs for your damaged ones. For your OEM needs, our team of professionals is available around the clock. We at WOC are happy to help you with any needs you may have in terms of automation. Please contact our team by phone or email for pricing and availability on any components and repairs.

What is the function of the Emergency Trip Terminal Board (ETTB)?

The ETTB collects and channels critical trip signals from safety devices to the turbine control system. It initiates an emergency shutdown when unsafe operating conditions are detected.

What types of input signals does the ETTB receive?

It typically receives 24 VDC discrete signals or dry contacts from field protection devices. These inputs are isolated and monitored for fault detection and fail-safe operation.

What voltage level is commonly used for the trip inputs?

Most trip inputs to the ETTB operate at 24 VDC, though some systems may use dry contact logic. The voltage level is standardized to match turbine control and safety systems.