World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS230TBAI - Analog Input/Output Terminal Board is available in stock which ships the same day.

IS230TBAI - Analog Input/Output Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230TBAI - Analog Input/Output Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

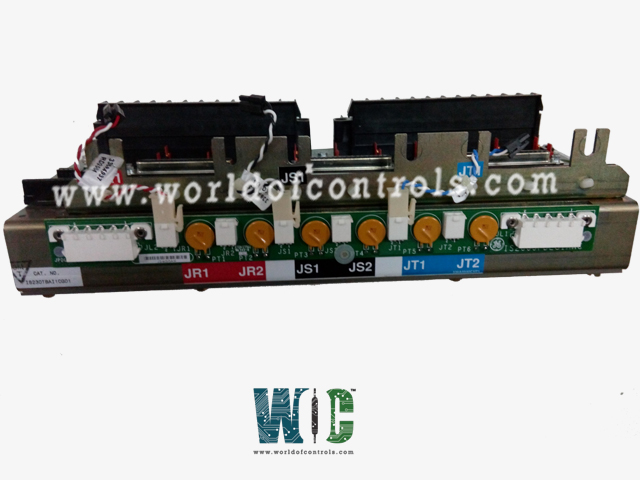

Part Number: IS230TBAI

Manufacturer: General Electric

Series: Mark VIe

Function: Analog Input/Output Terminal Board

Number of channels: 12 channels (10 AI, 2 AO)

Input span, transmitters: 1-5 V dc from 4-20 mA

Dimensions: 0.16 cm wide x 33.02 cm

Operating Temperature: -30 to 65°C

Controller and I/O module Redundancy: Simplex

Internal operating system: QNX

Operating Voltage: 9 V to 16 V dc

Power Consumption: 4 W

Maximumleadresistance: 15Ωmax

Output Load: 500 Ω for 4-20 mA

Analog outputs: 0 to 10 V

Outputs: 24 V

Configuration Software: ToolboxST

Ethernet Ports: 2 Ethernet ports

Country of Manufacture: United States (USA)

Availability: In Stock

Manual: GEH-6421M

FUNCTIONAL DESCRIPTION:

IS230TBAI is an Analog Input/Output Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The Analog Input terminal board supports 10 analog inputs and two outputs. The 10 analog inputs accommodate two-wire, three-wire, four-wire, or externally powered transmitters. The analog outputs can be set up for 0-20 mA or 0-200 mA current. Inputs and outputs have noise suppression circuitry to protect against surges and high-frequency noise. There are three DC-37 pin connectors provided on TBAI for connection to the I/O processors. Connections may be simplex on a single connector (JR1), or TMR using all three connectors. Connections may be through cables or directly to the electronics. In TMR applications, the input signals are fanned to the three connectors for the R, S, and T controls. TMR outputs operate by combining the current of the three connected output drivers and determining the total current with a measuring shunt on the TBAI. The TBAI then presents the total current signal to the electronics for regulation to the commanded setpoint.

INSTALLATION:

Connect the input and output wires directly to two I/O terminal blocks mounted on the terminal board. Each block is held down with two screws and has 24 terminals accepting up to #12 AWG wires. A shield terminal attachment point is located adjacent to each terminal block. TBAI can accommodate the following analog I/O types:

OPERATION:

A 24 V DC power source is available on the terminal board for all the transducers. There is a choice of current or voltage inputs using jumpers. One of the two analog output circuits is 4-20 mA, and the other can be jumper configured for 4-20 mA or 0- 200 mA. The same terminal board can be used for TMR applications. Transmitters/transducers can be powered by the 24 V DC source in the control system or can be independently powered. Terminal board jumpers J#A, J#B, and J0 set up the type of voltage and current inputs, and select the type of current output. Each output is monitored by diagnostics, and a suicide relay in the I/O controller disconnects the corresponding output if a fault cannot be cleared by a command from the processor.

In a TMR system, analog inputs fan out to the three I/O controllers (VAIC or PAIC). The 24 V dc power to the transducers comes from all three controllers and is diode shared on the terminal board. Each analog current output is fed by currents from all three controllers. The actual output current is measured with a series resistor, which feeds a voltage back to each I/O controller. The resulting output is the voted middle value (median) of the three currents.

CONFIGURATION:

The terminal board is configured by jumpers. For the location of these jumpers, refer to the installation diagram. The jumper choices are as follows:

WOC has the largest stock of OEM Replacement Parts for GE Distributed Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What types of analog signals are supported?

The board supports a wide range of signal types, including 2-wire, 3-wire, and 4-wire transmitters, along with externally powered devices. It accepts voltage inputs of ±5 V and ±10 V DC and current inputs of 4–20 mA. For analog outputs, two channels are provided that can be configured to deliver either 0–20 mA or 0–200 mA signals.

How is the board configured for different signal types?

Configuration is managed using onboard jumpers. Specific jumper pairs allow selection between voltage and current inputs, as well as determining whether the return path is connected to common. Additional jumpers configure the input current range and the output channel for either 20 mA or 200 mA, depending on application requirements.

How is signal configuration and mode selection managed?

Signal configuration is hardware-based and implemented through multiple sets of jumpers located on the PCB. Jumpers J1A–J8A select between current and voltage input modes, while J1B–J8B determine if the return path is common-grounded or floating. J9A/J10A are used to select 1 mA or 20 mA input ranges, and J0 configures one of the analog output channels for either 20 mA or 200 mA output.