World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

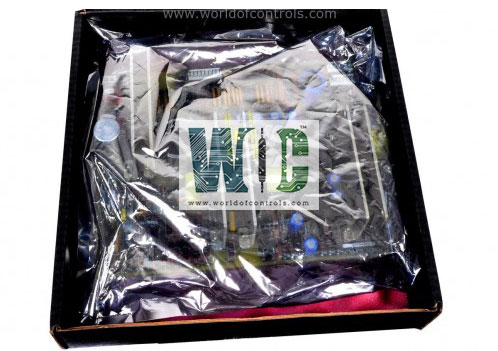

IS230STURH3A - Primary Turbine Protection Input Terminal Board is available in stock which ships the same day.

IS230STURH3A - Primary Turbine Protection Input Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230STURH3A - Primary Turbine Protection Input Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS230STURH3A

Manufacturer: General Electric

Series: Mark VIe

Product Type: Primary Turbine Protection Input Terminal Board

Technology: Surface Mount

Common Mode Voltage Range: ±5 V

Size: 15.9 cm high x 17.8 cm

Temperature: -30 to +65 degrees

No.of Analog Voltage Inputs: 6

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IS230STURH3A is a Primary Turbine Protection Input Terminal Board manufactured and designed by General Electric as part of the VIe Series used in GE Distributed Gas Turbine Control Systems. A Primary Turbine Protection Input Terminal Board, often referred to as a PTPI board, is a component used in industrial power generation and turbine control systems. It is a specialized terminal board designed to receive and process various input signals related to the operation and protection of a turbine, typically in power plants. Turbine protection systems are crucial for ensuring the safe and efficient operation of turbines in power plants. These systems monitor various parameters and conditions to prevent potential damage or failure of the turbine and its associated equipment. The PTPI board plays a key role in this protection scheme by serving as a central point where different sensors and instruments related to turbine operation are connected. The specific inputs that are connected to a PTPI board can vary depending on the type of turbine and the requirements of the power plant. Some common types of signals that might be connected to a PTPI board include:

Temperature Sensors: These sensors monitor the temperature of different parts of the turbine, such as bearing temperatures, exhaust temperatures, and cooling system temperatures.

Pressure Sensors: Pressure sensors measure the pressure levels within the turbine and its associated systems, including steam pressure and hydraulic pressure.

Vibration Sensors: Vibration sensors detect any abnormal vibrations or movements in the turbine's rotating components, helping to identify potential mechanical issues.

Speed Sensors: Speed sensors monitor the rotational speed of the turbine shaft and can trigger alarms or shutdowns if the speed deviates from the safe operating range.

Position Sensors: These sensors detect the positions of various components, such as valves and dampers, and ensure they are in the correct positions for safe operation.

WOC has the largest stock of GE Distributed Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What is a Primary Turbine Protection Input Terminal Board (PTPI board)?

A PTPI board is a specialized component used in industrial power generation systems, particularly in turbines, to receive, process, and manage input signals from various sensors and instruments related to turbine operation and protection.

What types of input signals are connected to a PTPI board?

Input signals connected to a PTPI board can include temperature, pressure, vibration, speed, flow, position, and level measurements from sensors located throughout the turbine and its associated systems.

How is the information from the PTPI board communicated to the control system?

The PTPI board communicates with the control system through various communication protocols, such as analog signals, digital signals, or Fieldbus protocols, depending on the system's architecture and the level of automation.