World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

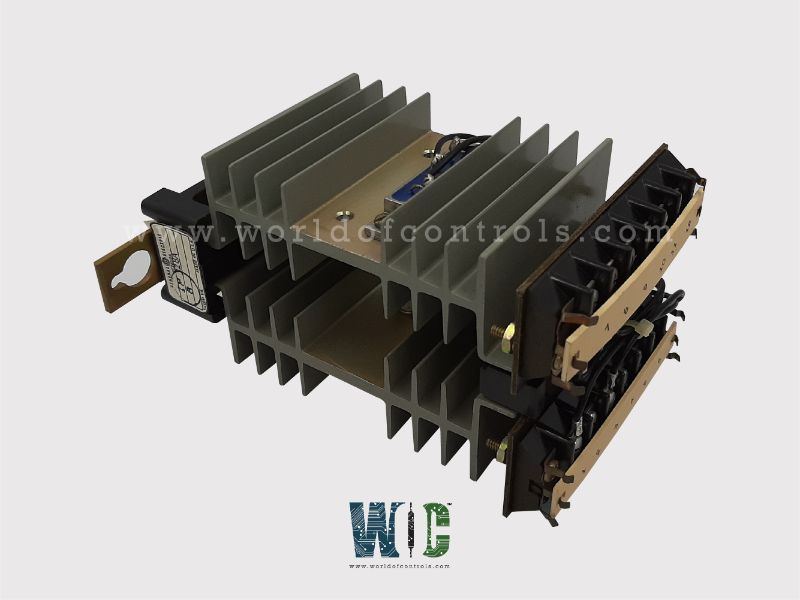

IC3603A330A - Heat Sink Assembly Module is available in stock which ships the same day.

IC3603A330A - Heat Sink Assembly Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3603A330A - Heat Sink Assembly Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: IC3603A330A

Manufacturer: General Electric

Product Type: Heat Sink Assembly Module

Series: Mark I & II

Input Voltage: 100-240V AC, 50/60Hz

Output Current: 0.15 A AMP

Output Voltage Range: 0-50V DC

Operating Temperature: 0°C to 40°C

Resolution: 10mV/10mA

Availability: In Stock

Weight: 2.5 kg

Dimensions: 6.00 x 6.00 x 5.00

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3603A330A is a Heat Sink Assembly Module manufactured and designed by General Electric and is part of the Mark II Series used in Static Starter Control systems. A heat sink assembly module is an essential component in electronic devices designed to manage and dissipate the heat produced by critical parts such as processors, power transistors, and other high-performance elements. When electronic components operate, they generate heat as a byproduct of power consumption. Without an effective heat dissipation mechanism, this heat can accumulate, leading to elevated temperatures that compromise the device’s performance, reduce efficiency, and, if unchecked, may even cause component failure or shorten the overall lifespan of the device.

The heat sink assembly functions by absorbing the heat from these components and then dispersing it away from the device, usually through fins or a thermally conductive material that increases the surface area exposed to ambient air. This setup allows for faster cooling, ensuring that internal temperatures remain within a safe operational range. Heat sinks are often combined with other thermal management techniques such as thermal pads, fans, or liquid cooling systems to enhance the cooling process further.

FUNCTIONS OF HEAT SINK ASSEMBLY MODULES:

WOC has the largest stock of replacement parts for GE Speedtronic Gas turbine control systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

Why is effective heat dissipation important in turbine control systems?

Turbine control systems operate under high-power loads and harsh environments, generating significant heat. Without effective heat dissipation, components can overheat, leading to equipment malfunction, reduced efficiency, or even system failure, which can disrupt turbine operations.

What components in turbine control systems typically require heat sink modules?

Key components include power modules, voltage regulators, microcontrollers, and power transistors. These parts handle significant power and heat output, making effective cooling essential for optimal performance and longevity.

How does a Heat Sink Assembly Module improve turbine control system reliability?

By preventing excessive temperatures, the heat sink module helps maintain stable operations and protects sensitive electronic components. This minimizes the risk of thermal-induced failures, ensuring reliable turbine control and reducing downtime.