World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

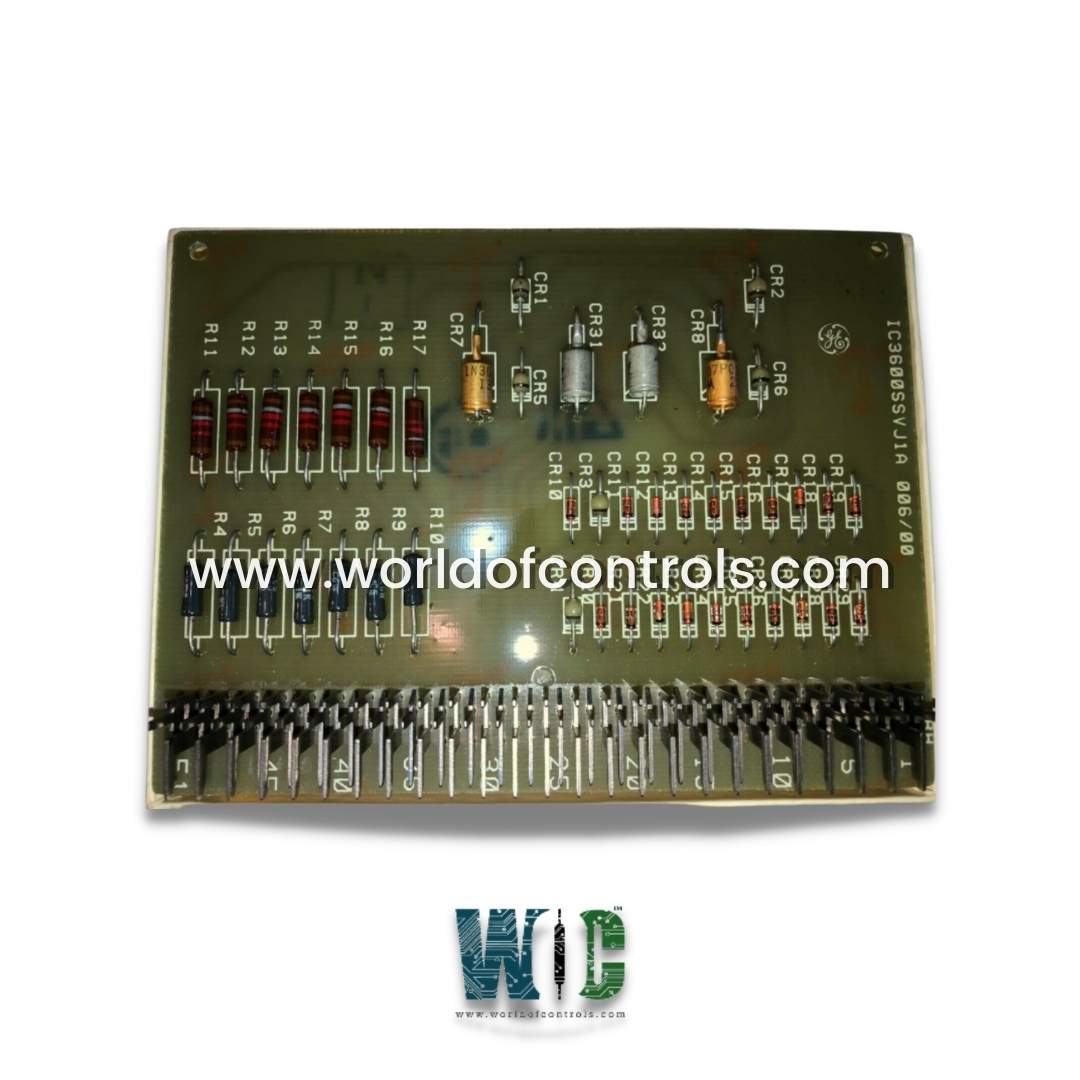

IC3600SSVJ1 - Servo Valve Protection Card is available in stock which ships the same day.

IC3600SSVJ1 - Servo Valve Protection Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SSVJ1 - Servo Valve Protection Card, contact us and we will get back to you within 24 hours.

Part No: IC3600SSVJ1

Manufacturer: General Electric

Function: Servo Valve Protection Card

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

IC3600SSVJ1 is a Servo Valve Protection Card developed by GE. It is a part of the Mark I and II control system. It is designed to protect servo valves by monitoring and controlling the electrical signals sent to the valve, ensuring it operates within its safe operating parameters. This protection helps prevent damage caused by overcurrent, overvoltage, overheating, and other potential issues, ultimately improving the reliability and lifespan of the servo valve and associated systems.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is IC3600SSVJ1?

It is a Servo Valve Protection Card developed by GE.

Which systems are compatible with the Card?

It is designed for use within GE's Speedtronic Mark I and II control systems, which are widely used in gas turbines, and steam turbines.

What are the key functions of the board?

Overcurrent protection to prevent damage to the servo valve. Voltage regulation to ensure the servo valve receives stable and safe voltage. Temperature monitoring to avoid overheating and potential valve failure. Signal conditioning to maintain accurate control signals for optimal valve operation. Fault detection and diagnostics to alert operators of any issues.

How does the card protect the servo valve?

Monitoring the electrical current and disconnecting power in the case of overcurrent. Regulating voltage to prevent excessive spikes. Monitoring temperature to ensure the servo valve does not overheat. Detecting faults and providing diagnostic signals to alert operators of issues.