SPECIFICATIONS

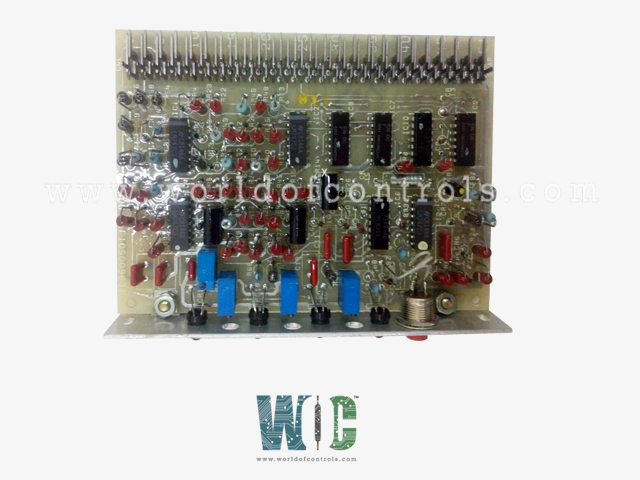

Part No: IC3600SOTE1

Manufacturer: General Electric

Function: Over Temperature Drive Card

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

Functional Description

IC3600SOTE1 is a Temperature Drive Card developed by GE. It is a part of the Mark I and II control system. It specifically addresses temperature-related concerns by offering precise control and monitoring capabilities, ensuring equipment and systems operate within safe temperature ranges. This module is particularly useful in gas and steam turbine applications, where temperature management is critical.

Characteristics

- Real-time temperature monitoring and precise control to maintain safe operational ranges.

- Converts temperature signals into logic signals, enabling the control system to adjust turbine or equipment operating parameters efficiently.

- Includes multiple onboard components such as thermistors, resistors, capacitors, and operational amplifiers, ensuring signal accuracy and stability.

- Integrated modular design, suitable for installation in GE's control system slots.

- Standardized pins and connectors for seamless compatibility with Speedtronic systems. Input ports to receive temperature sensor signals and output ports to transmit control signals.

- Industrial-grade components capable of operating in harsh environments. Resistant to electromagnetic interference (EMI) and environmental noise, ensuring consistent performance.

Product Attributes

- Temperature Measurement Range: Typically -40°C to +120°C, depending on the connected temperature sensor.

- Operating Voltage: Usually 24V or 48V DC, matching the control system requirements.

- Input: Analog signals from thermocouples or thermistors.

- Output: Digital or analog signals are transmitted to the control unit.

- Operational Temperature: -20°C to +70°C.

- Humidity: 0% to 95% (non-condensing).

- Size and Compatibility: Designed for easy installation and quick replacement within Speedtronic systems.

Features

- Within the operational framework of the system, the Overtemperature Protection System demonstrates a robust and reliable structure by incorporating dual, independent channels for enhanced safety and redundancy. Each channel within this system focuses on the critical task of monitoring and managing temperature levels within the turbine exhaust duct, where temperature control is of paramount importance. This dual-channel setup is designed to provide a comprehensive and redundant approach to safeguarding the system and its processes.

- System is the use of three thermocouples within each channel. These thermocouples are strategically placed in the turbine exhaust duct, where they constantly measure and transmit temperature data. By utilizing multiple thermocouples, the system gains a broader perspective on temperature conditions, ensuring greater accuracy and reliability in temperature monitoring.

- It serves as an essential component for detecting and responding to potentially dangerous overspeed conditions in the system. It acts as a safety mechanism, ready to intervene should the system's speed exceed safe limits.

- Temperature Averaging Cabinet performs in gathering and processing temperature data from the thermocouples. Temperature Averaging Cabinet is the same one used in the temperature control loop, illustrating a streamlined approach to system design and smart utilization of resources. This shared use not only optimizes system efficiency but also ensures consistency in data handling.

- The presence of dual channels in the Overtemperature Protection System reflects redundancy. If one channel experiences a malfunction or failure, the other channel can immediately take over, preventing disruptions and potential hazards.

- By monitoring temperature levels in the exhaust duct with precision and redundancy, the Overtemperature Protection System is capable of initiating protective actions when required. Whether it's regulating temperature within acceptable limits or responding to overspeed conditions, the system plays a critical role in ensuring the safe and efficient operation of the turbine.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is IC3600SOTE1?

It is a Temperature Drive Card developed by GE

How does the system achieve redundancy and enhanced safety?

The system incorporates dual, independent channels, providing redundancy. If one channel experiences a malfunction, the other can take over to prevent disruptions and potential hazards.

What kind of sensors does the system use for temperature monitoring?

The system utilizes three thermocouples within each channel, strategically placed in the turbine exhaust duct to constantly measure and transmit temperature data.

Why is the use of multiple thermocouples important in the system?

Multiple thermocouples provide a broader perspective on temperature conditions, enhancing the accuracy and reliability of temperature monitoring.