World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

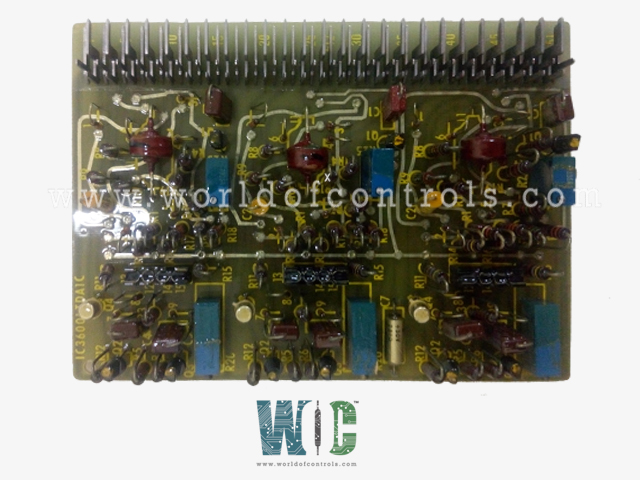

IC3600LTDA1 - Load Temperature Detector Amplifier Card is available in stock which ships the same day.

IC3600LTDA1 - Load Temperature Detector Amplifier Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600LTDA1 - Load Temperature Detector Amplifier Card, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IC3600LTDA1

Manufacturer: General Electric

Series: Mark II

Product Type: Load Temperature Detector Amplifier Card

Input Voltage Range: 24 VDC

Operating Temperature: -20°C to +70°C

Board Size: 16.51 cm High x 17.8 cm

Number of Inputs: 2-4 channels

Supported Sensors: Thermocouples (Types J, K, T,)

Repair: 3-7 Days

Weight: 0.5 kg

Country of Origin: USA

Availability: In Stock

FUNCTIONAL DESCRIPTION:

IC3600LTDA1 is a Load Temperature Detector Amplifier Card manufactured and designed by General Electric as part of the Mark II Series used in GE Speedtronic turbine control systems. The Load Temperature Detector Amplifier Card is designed to interface with temperature sensors that are installed in various parts of the turbine. These sensors provide real-time temperature readings of critical components, such as the turbine casing, exhaust gases, and combustion chambers. The amplifier card processes these temperature signals and sends them to the turbine's control system, ensuring optimal operation based on thermal feedback.

FUNCTIONS:

WOC has the largest stock of GE Speedtronic gas turbine control systems OEM replacement parts. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a Load Temperature Detector Amplifier Card?

A Load Temperature Detector Amplifier Card is a component used in turbine control systems to process, amplify, and monitor temperature signals from sensors in gas or steam turbines. It ensures accurate temperature data is provided to the control system, allowing for optimal turbine performance and thermal regulation.

What does a Load Temperature Detector Amplifier Card do?

The card amplifies weak signals from temperature sensors (like thermocouples or RTDs) placed throughout the turbine system, conditions these signals to remove noise or interference, and sends them to the turbine control system. This allows the control system to monitor temperatures and make necessary adjustments to maintain safe and efficient turbine operation.

Why is load temperature monitoring important in turbines?

Monitoring load temperature is critical for ensuring the turbine operates efficiently and within safe thermal limits. Excessive temperatures can cause overheating, leading to equipment damage or reduced lifespan, while operating at lower-than-optimal temperatures can decrease turbine efficiency.