SPECIFICATIONS

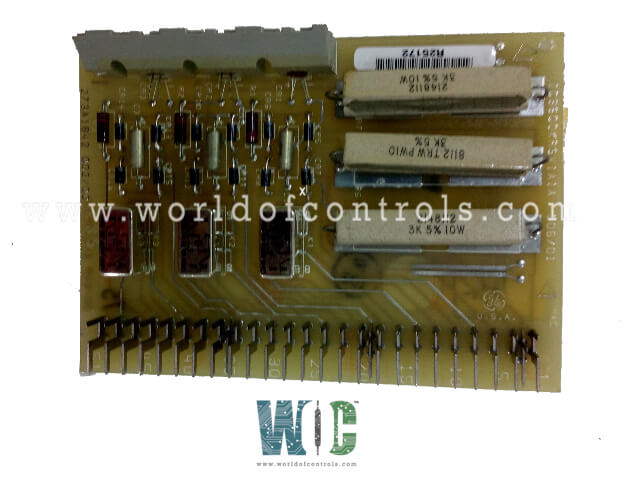

Part No.: IC3600KRSV1A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature Operating: -30 to 65oC

Product Type: Relay Circuit Board

Availability: In Stock

Series: Mark I and II

Functional Description

IC3600KRSV1A is a relay circuit board developed by GE. It is a part of Mark I and II control system. The system is designed to provide fully automatic control of both the gas turbine and the load system. This sophisticated control system utilizes the latest advancements in electronic technology to ensure efficient, reliable, and safe operation.

Features

- Advanced Electronic Technology: The control system incorporates state-of-the-art electronic components, including integrated circuits and microprocessors. These components enable precise control, sequencing, and protective functions necessary for the efficient operation of gas turbines.

- Automatic Control: The system is designed to provide fully automatic control over the gas turbine and its associated load system. This automation ensures consistent performance and reduces the need for manual intervention, allowing for smoother and more reliable operation.

- Sensors and Servo Actuators: The control system includes a variety of sensors and servo actuators mounted directly on the turbine. These devices provide essential input and output interfacing, enabling the control system to monitor and adjust turbine parameters in real-time.

- Reliability Through Redundancy: To achieve high reliability, the system employs redundancy for critical control functions. This includes redundant speed and temperature control mechanisms, ensuring that the turbine can continue to operate safely even if one component fails.

- High Performance and Accuracy: The system delivers high performance, accuracy, and fast response times, with virtually no deadband. This is accomplished through electronic computation and the use of high-resolution hydraulic servos, which provide precise control over turbine operations.

- Independent Protective System: The protective system within the control framework is designed to be virtually independent of the main control equipment. It employs a high degree of redundancy to ensure reliable and safe machine operation, protecting the turbine from potential faults or hazardous conditions.

Functional Overview

- Control Functions: The system manages various control functions, including regulating turbine speed and load, maintaining optimal temperature levels, and ensuring efficient combustion processes. These functions are critical for maximizing turbine efficiency and performance.

- Sequencing Functions: The control system orchestrates the startup, operation, and shutdown sequences of the gas turbine, ensuring that each step is carried out smoothly and safely. This sequencing capability helps prevent operational errors and extends the life of the turbine.

- Protective Functions: The system includes numerous protective features designed to safeguard the turbine from damage. These features include automatic shutdown mechanisms in case of critical faults, temperature and pressure monitoring, and emergency stop capabilities.

The WOC team is always available to help you with your Mark I and II requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IC3600KRSV1A?

It is a relay circuit board�developed by GE under the Mark I and II series.

What are the key protective functions included in the system?The key protective functions are overspeed protection, overtemperature protection, lube oil pressure and temperature monitoring, loss of flame detection, and vibration monitoring.

How does the system handle overspeed conditions?

The system monitors the turbine's rotational speed, and if it exceeds safe limits, it triggers a shutdown to prevent mechanical failure.

What happens if the temperature of critical components exceeds safe thresholds?

If temperatures exceed safe thresholds, the system initiates a shutdown to avoid overheating and potential damage to the turbine components.