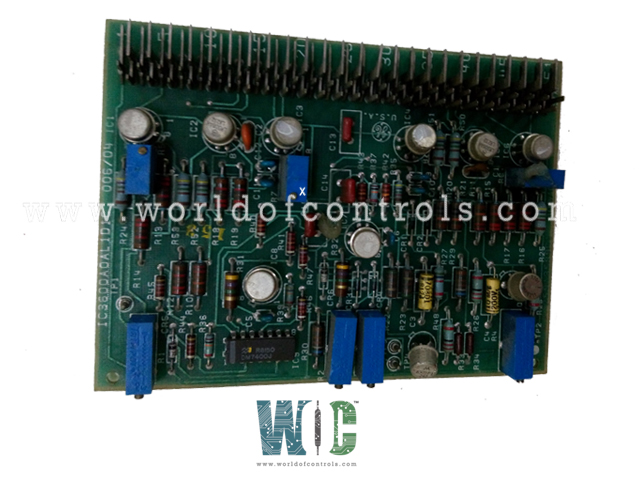

SPECIFICATIONS

Part No.: IC3600AOAL1D

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature Operating: -30 to 65oC

Product Type: Operational Amplifier Board

Availability: In Stock

Series: Mark I and II

Functional Description

IC3600AOAL1D is an operational amplifier board developed by GE. It is a part of Mark I and II control system. The protective systems in General Electric's gas turbines are meticulously designed to detect abnormal operating conditions and safely shut down the turbine to prevent damage. These systems employ a combination of advanced technology and redundancy to ensure high reliability and safety.

Features

- Overspeed Protection: The system monitors the turbine's rotational speed to ensure it does not exceed safe limits. If an overspeed condition is detected, the protective system initiates a shutdown to prevent mechanical failure.

- Overtemperature Protection: Sensors continuously monitor the temperature of critical components, such as the combustion chamber and turbine blades. If temperatures exceed safe thresholds, the system triggers a shutdown to avoid overheating and potential damage.

- Lube Oil Pressure and Temperature Monitoring: The protective system ensures that the lubrication oil pressure and temperature remain within optimal ranges. Abnormalities in lube oil parameters can indicate potential issues in the lubrication system, prompting a shutdown to protect the turbine's moving parts.

- Loss of Flame Detection: The system includes sensors to detect the presence of flame in the combustion chamber. A loss of flame can lead to unburned fuel accumulation and potential hazards. The system shuts down the turbine to prevent such risks.

- Vibration Monitoring: Excessive vibration can indicate mechanical issues or imbalances within the turbine. Vibration sensors monitor these levels, and if they exceed acceptable limits, the system initiates a shutdown to prevent damage.

Additional Protective Features

- Combustion System Malfunction Detection: Monitors for irregularities in the combustion process that could affect performance and safety.

- Compressor Stall Detection: Identifies compressor stalls that can lead to reduced efficiency and potential damage.

- Fire Detection: Includes sensors to detect fire within the turbine enclosure, triggering an immediate shutdown to prevent catastrophic damage.

- Alarm and Shutdown: In most cases, the protective system is designed to provide an early warning before initiating a shutdown. If a monitored parameter approaches a critical threshold, the system activates an alarm, alerting operators to the potential issue. This early warning allows operators to take corrective action before a shutdown is necessary.

- Manual Emergency Shutdown: The system includes a manual emergency shutdown feature that can be activated by operators. This function allows for immediate turbine shutdown in case of emergencies or situations where automatic systems may not respond quickly enough.

Redundancy for High Reliability

- Redundant Shutdown Devices: At least two separate means of shutting off the fuel supply are provided, typically through two independent fuel shutoff valves.

- Redundant Sensors: Critical functions, such as speed, temperature, and pressure monitoring, are equipped with redundant sensors. This redundancy ensures that the protective system can function effectively even if one sensor fails.

The WOC team is always available to help you with your Mark I and II requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IC3600AOAL1D?

It is an operational amplifier board developed by GE under the Mark I and II series.

What does the system do if a loss of flame is detected in the combustion chamber?

If a loss of flame is detected, the system shuts down the turbine to prevent the accumulation of unburned fuel, which could pose safety risks.

Why is vibration monitoring important?

Excessive vibration can indicate mechanical issues or imbalances. The system monitors vibration levels and initiates a shutdown if they exceed acceptable limits to prevent damage.