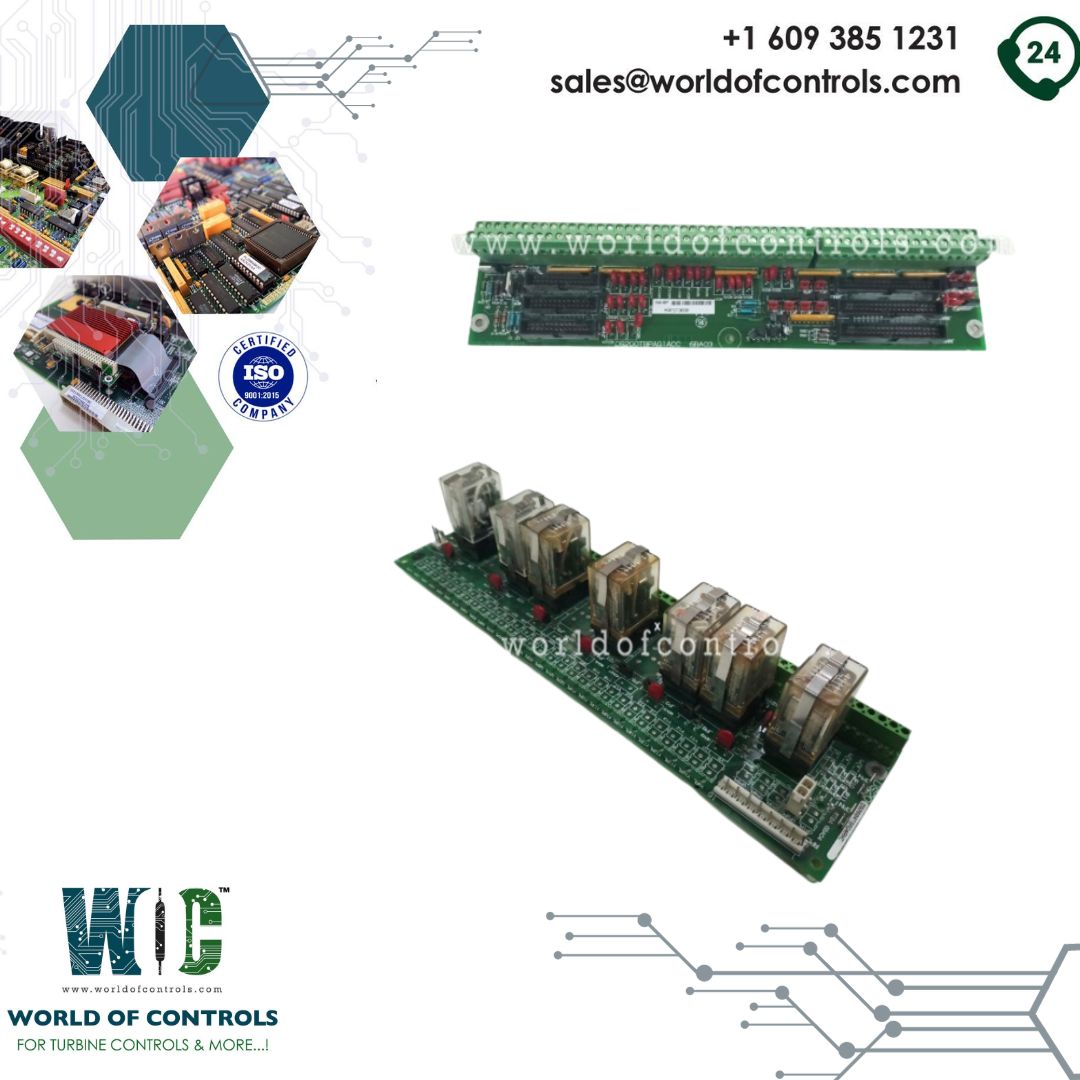

GE Speedtronic Mark V Terminal Board serves as an interface within the Mark V control system. It allows for the connection of various sensors, transducers, and devices to the control system. It typically includes multiple input and output terminals. These connectors facilitate connection of sensors, actuators, and other field devices to the control system.

The Mark V system manages inlet guide vanes and water or steam injection to align with emissions and operational standards. In cases involving Dry Low NOx techniques, it handles fuel staging and combustion mode, closely monitoring the entire process.

The system excels in sequencing auxiliaries, enabling fully automated startup, shutdown, and cooldown procedures. It also offers robust protection for the gas turbine against unfavorable operating conditions, promptly alerting operators to abnormal situations.

The operator interface consists of a color graphic monitor and keyboard, providing real-time feedback on current operating conditions. Operator input commands are executed using a cursor positioning device, ensuring safe and deliberate turbine operation.

Communication between the operator interface and the turbine control occurs via the Common Data Processor (C) linked to control processors R, S, and T. The system also supports communication with remote and external devices. For critical applications, a redundant operator interface is available to safeguard external data links.

The Mark V Control System boasts Self-Initiated Fault Tolerance (SIFT) technology, effectively protecting against module failures and data error propagation. Built-in diagnostics facilitate extensive troubleshooting, including diagnostics during power-up, background checks, and manual diagnostic routines for precise fault identification down to the board and circuit levels.

Set points, tuning parameters, and control constants can be dynamically adjusted during operation, with a security password system in place to ensure authorized access only. This feature allows fine-tuning of the control system for optimal performance.

WOC is happy to assist you with any of your GE Speedtronic Mark V Terminal Board requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What types of signals can be connected to the terminal board?

The terminal board can handle various types of signals, including those from sensors measuring parameters like temperature, pressure, and speed. It can also accommodate control signals for actuators and valves.

Why is signal isolation important in GE Speedtronic Mark V Terminal Board?

Signal isolation is crucial for preventing electrical noise or faults in one part of the system from affecting other components. It helps maintain the integrity of control signals and data.

Does the GE Speedtronic Mark V Terminal Board support redundancy for reliability?

In some applications, the terminal board may support redundancy to enhance system reliability. Redundant terminal boards or connections can ensure continued operation even if one component fails.

How is diagnostic and monitoring capability implemented in the terminal board?

The terminal board may include diagnostic features that allow for the monitoring of signals and the detection of faults or anomalies in connected devices. This information is essential for troubleshooting and ensuring safe operation.