World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

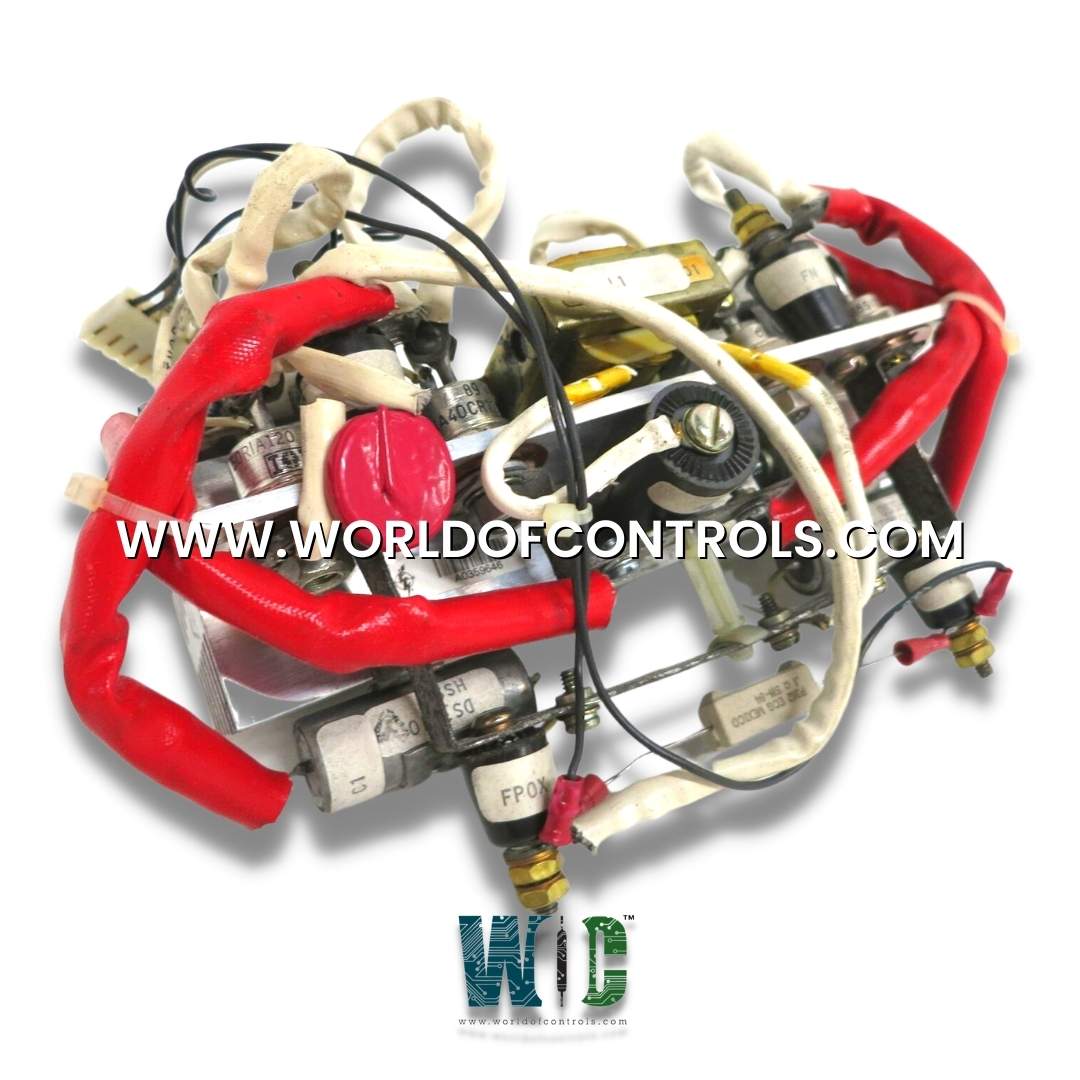

DS3820HSMC1 - Heat Sink Assembly Module is available in stock which ships the same day.

DS3820HSMC1 - Heat Sink Assembly Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3820HSMC1 - Heat Sink Assembly Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: DS3820HSMC1

Manufacturer: General Electric

Series: Mark IV

Product Type: Heat Sink Assembly Module

Heat Dissipation Capacity: 300 Watts

Current per TEC Series: 7.5 A

Voltage per TEC Series: 40 V

Fan Voltage: 7.0 ~ 13.5 VDC

Fan Power: 16 W

Noise Level per Fan: 50 dBA

Input Range: 0-10 V, 4-20 mA

Power Requirements: 24V DC,

Output Range: 0-10 V, 4-20 mA

Dimensions: 13.528 x 8.466 x 3.820

Operating Temperature: -20°C to +70°C

Weight: 5 kg

Country of Origin: USA

Availability: In Stock

FUNCTIONAL DESCRIPTION:

DS3820HSMC1 is a Heat Sink Assembly Module manufactured and designed by General Electric and is part of the Mark IV Series used in GE Speedtronic gas turbine control systems. A Heat Sink Assembly Module is an essential component designed to manage and dissipate the heat generated by electronic devices, ensuring they operate within safe temperature limits. These modules are crucial in maintaining the reliability and longevity of components such as CPUs, GPUs, power transistors, and other high-power semiconductors by preventing overheating. The assembly typically includes a heat sink, often made from materials like aluminum or copper due to their excellent thermal conductivity properties.

The heat sink features a series of fins that increase the surface area in contact with the cooling medium, usually air, thereby enhancing heat dissipation. In addition to the heat sink, the assembly often includes thermal interface materials (TIM) like thermal paste or pads that ensure efficient heat transfer between the component and the heat sink. Some heat sink modules incorporate fans or blowers to enhance air movement across the fins, known as active cooling solutions, while passive heat sinks rely solely on natural convection. The design and structure of a heat sink can vary significantly, tailored to the specific thermal management needs of different applications. These modules are indispensable in a wide range of industries, from computing and power electronics to LED lighting and automotive electronics, providing critical thermal management to ensure optimal performance and durability of electronic devices.

FUNCTIONS:

WOC has the largest stock of OEM replacement parts for GE Speedtronic Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What materials are commonly used in heat sinks?

Common materials include aluminum, which is lightweight and cost-effective, and copper, which has superior thermal conductivity but is heavier and more expensive. Some high-performance heat sinks may use a combination of these materials.

What is thermal interface material (TIM), and why is it important?

Thermal interface material (TIM) is a substance applied between the electronic component and the heat sink to fill microscopic gaps and improve thermal conductivity. It is crucial for efficient heat transfer and effective cooling.

What is the difference between passive and active heat sinks?

Passive heat sinks rely solely on natural convection to dissipate heat and do not include any moving parts. Active heat sinks incorporate fans or blowers to enhance air movement and improve heat dissipation efficiency.