World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

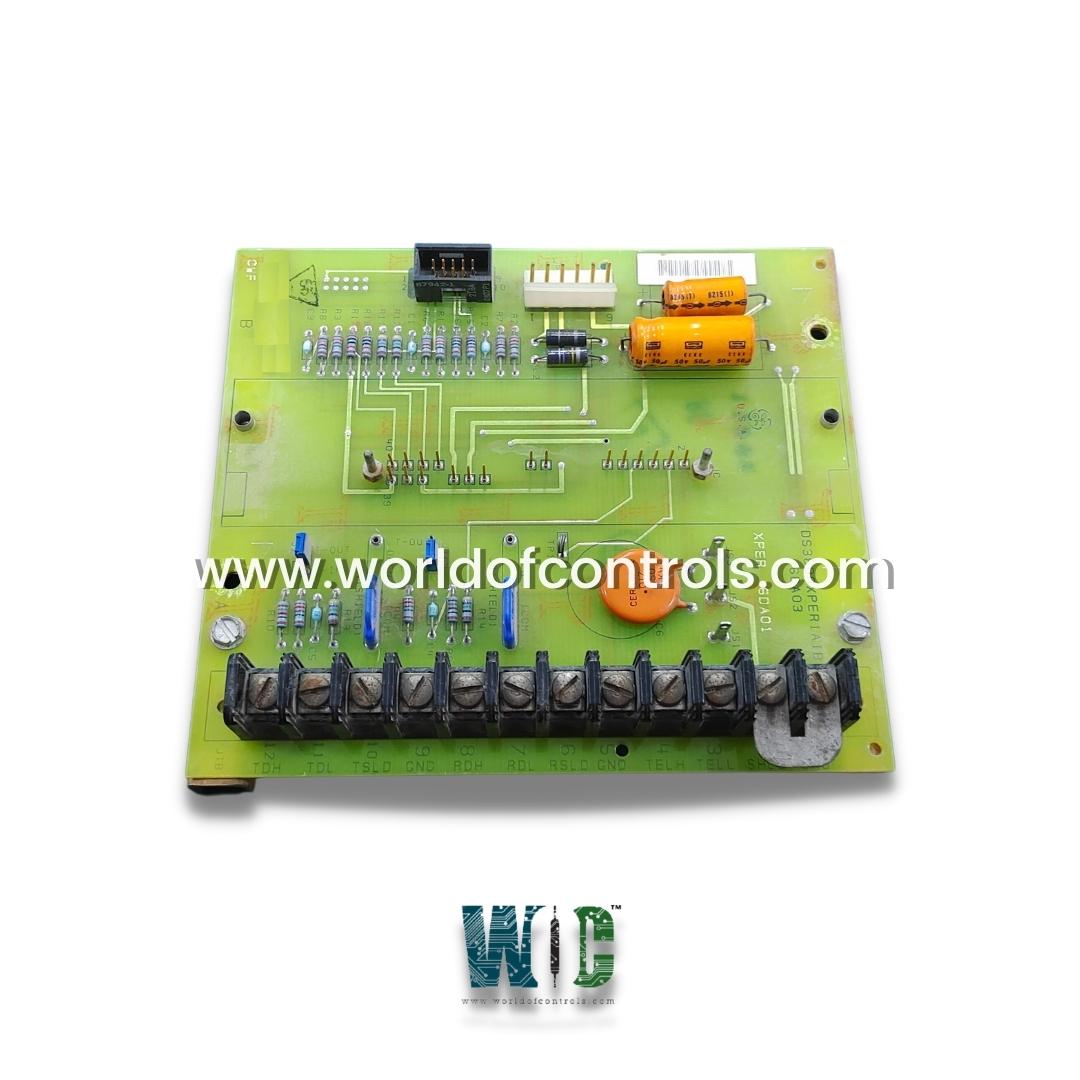

DS3800XPER1A - Data Link Isolation Board is available in stock which ships the same day.

DS3800XPER1A - Data Link Isolation Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800XPER1A - Data Link Isolation Board, contact us and we will get back to you within 24 hours.

Part No.: DS3800XPER1A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Product Type: Data Link Isolation Board

Availability: In Stock

Series: Mark IV

DS3800XPER1A is a Data Link Isolation Board developed by GE. It is a part of mark IV control system. A Data Link Isolation Board is used in control systems to ensure safe, reliable, and uninterrupted communication between various modules within a system. It plays a critical role in isolating and protecting data communication channels from electrical noise, surges, and other disturbances, which can compromise system integrity.

The WOC team is always available to help you with your Mark IV requirements. For more information, please contact WOC.

What is DS3800XPER1A?

It is a Data Link Isolation Board developed by GE under the Mark IV series.

What is the purpose of the Board?

Provides electrical isolation to prevent interference or faults from affecting other parts of the system. Protects sensitive components from electrical surges or noise. Maintains data integrity for accurate communication and control.

How does a Data Link Isolation Board enhance system safety?

By isolating communication lines, the board prevents electrical faults, such as ground loops and voltage spikes, from spreading through the system. This isolation protects both the equipment and personnel from potential hazards.

How do I maintain a Data Link Isolation Board?

Regularly inspect the board for physical damage, corrosion, or loose connections. Use diagnostic tools to monitor performance. Replace damaged components with genuine parts to ensure compatibility. Clean connectors to prevent signal disruption.