World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

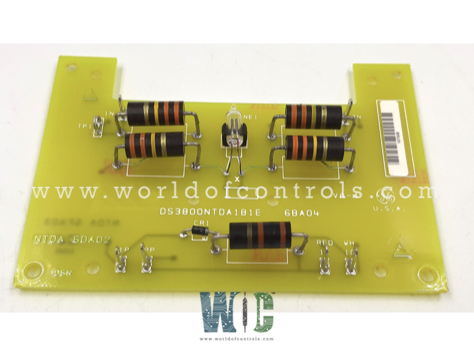

DS3800NTDA1B - Control Display Digital Card is available in stock which ships the same day.

DS3800NTDA1B - Control Display Digital Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NTDA1B - Control Display Digital Card, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800NTDA1B

Manufacturer: General Electric

Series: Mark IV

Product Type: Control Display Digital Card

Power Requirements: +5 V dc

Power supply voltage: 24 V dc

Operating temperature: -35 to +55°C

Size: 15.7 cm high x 18.5 cm

Weight: 0.5kg

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800NTDA1B is a Control Display Digital Card manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. A gas turbine control system is a sophisticated framework designed to regulate and monitor the operations of a gas turbine. These systems include various components such as sensors, actuators, control algorithms, and user interfaces. Their primary role is to maintain optimal performance, ensure safety, and improve the efficiency of power generation processes. Control display digital cards are integral to gas turbine control systems. These digital cards function as the central processing units, managing data from various sensors and executing control algorithms to regulate turbine operations. They also provide a user interface for real-time monitoring and adjustments.

COMPONENTS OF CONTROL DISPLAY DIGITAL CARDS:

HOW DO CONTROL DISPLAY DIGITAL CARDS WORK?

Control display digital cards process signals from various sensors installed in the turbine. These signals are analyzed, and appropriate control commands are generated to adjust turbine parameters such as fuel flow, temperature, and pressure. The digital card also displays this data to operators, enabling them to make informed decisions and adjustments.

TYPES OF CONTROL DISPLAY DIGITAL CARDS:

WOC has the largest stock of GE Speedtronic Gas turbine control systems replacement parts. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What are the main functions of a control display digital card?

The primary functions include processing sensor data, executing control algorithms, and providing real-time operational data to operators.

How does a control display digital card improve gas turbine efficiency?

By offering precise control and real-time monitoring, these cards optimize turbine performance, leading to improved efficiency.

How often should control display digital cards be maintained?

Routine maintenance, including regular diagnostics and firmware updates, should be conducted to ensure optimal performance.