World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

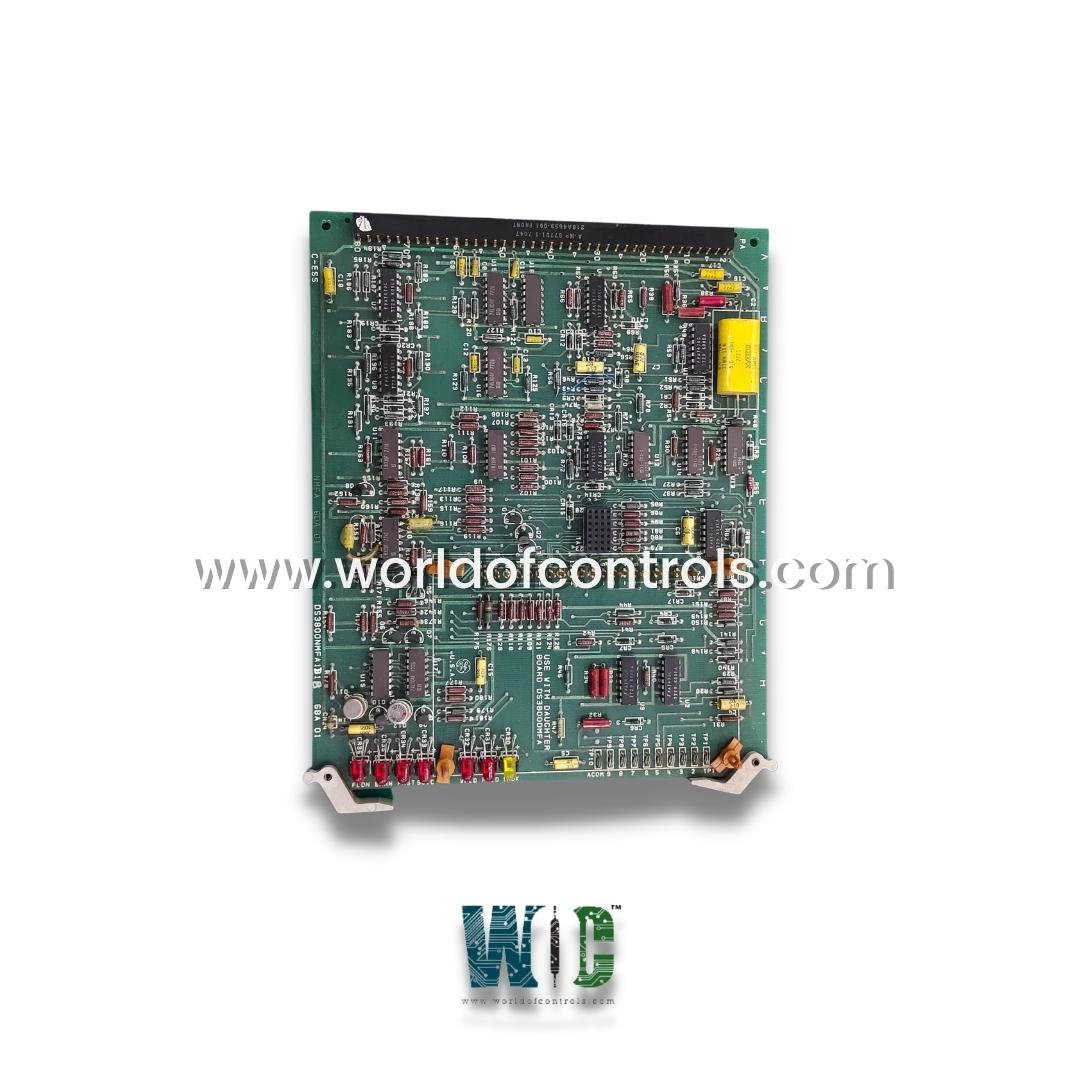

DS3800NMFA1B - Motor Field Regulator Board is available in stock which ships the same day.

DS3800NMFA1B - Motor Field Regulator Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NMFA1B - Motor Field Regulator Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800NMFA1B

Manufacturer: General Electric

Series: Mark IV

Product Type: Motor Field Regulator Board

Number of channels: 16

Input Voltage Range: 24V DC

Operating temperature: -35 to 60 °C

Size: 8.26 cm high x 4.18 cm

Repair: 3-7 Day

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800NMFA1B is a Motor Field Regulator Board manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. The Motor Field Regulator Board (MFRB) is a vital component within gas turbine control systems, specifically designed to regulate the electrical current supplied to the field windings of the turbine generator. Its primary function is to control the generator's output voltage, ensuring stable and efficient operation under varying load conditions.

FUNCTIONS OF THE MOTOR FIELD REGULATOR BOARD:

WOC has the largest stock of OEM replacement parts for GE Speedtronic Gas Turbine Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a gas turbine Motor Field Regulator Board?

The MFRB is a crucial component that regulates the electrical current supplied to the field windings of the turbine generator. It controls the generator's output voltage, ensuring stable operation and efficient power generation.

How does the Motor Field Regulator Board work?

The MFRB adjusts the field current based on operational requirements and load conditions. By varying the field current, it regulates the generator's output voltage and manages power generation efficiency. It also integrates with the turbine control system to monitor and protect against electrical faults.

How are boards packaged for shipment from WOC?

Parts are placed in antistatic packets and securely packed in ESD boxes cushioned with ESD Foam designed to safeguard electrical components.