World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

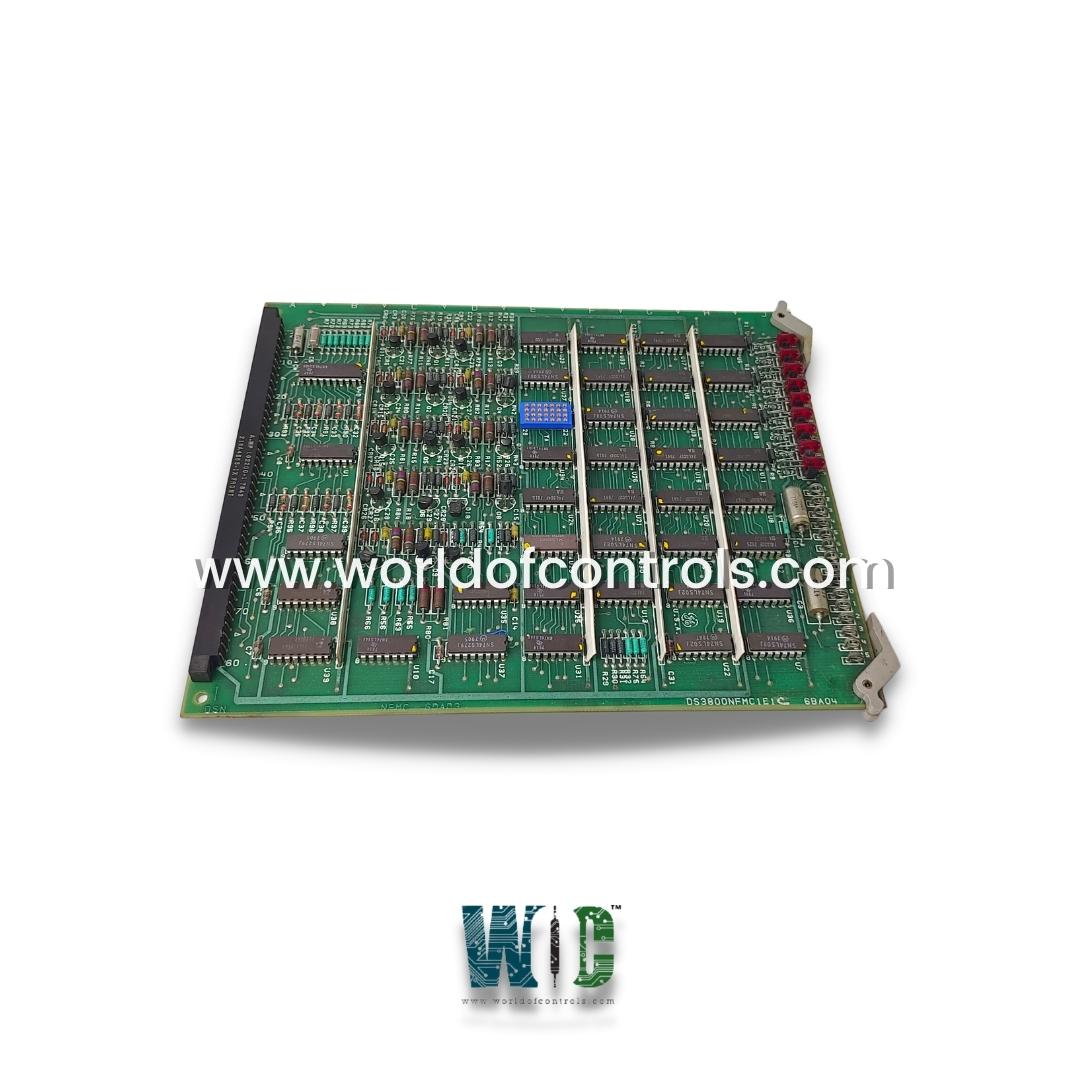

DS3800NFMC1E - Fault Finder Board is available in stock which ships the same day.

DS3800NFMC1E - Fault Finder Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NFMC1E - Fault Finder Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800NFMC1E

Manufacturer: General Electric

Series: Mark IV

Product Type: Fault Finder Board

Number of relay channels: 12

Power supply voltage: 24 V dc

Operating temperature: -40 to +65°C

Size: 15.7 cm high x 17.8 cm

Weight: 0.9kg

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800NFMC1E is a Fault Finder Board manufactured and designed by General Electric and is part of the Mark IV Series used in GE Speedtronic gas turbine control systems. The FFB continuously monitors various signals and parameters within the system to identify anomalies or deviations from expected values, which may indicate a fault. Upon detecting a potential issue, the board analyzes the data to diagnose the nature and location of the problem, generating alarms or alerts to notify operators of the detected faults. This allows for timely interventions and helps prevent damage or operational disruptions. It integrates seamlessly with other system components, such as the General Purpose Multiply Board (GPMB) and various sensors, to ensure comprehensive monitoring and diagnostics. By isolating faults through systematic testing and analysis, the FFB enables accurate identification of faulty components or subsystems.

FUNCTIONS:

WOC has the largest stock of OEM replacement parts for GE Speedtronic Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How does the FFB detect faults?

The FFB continuously monitors various signals and parameters from the turbine control system. It uses advanced algorithms to identify deviations from normal operating conditions that may indicate a fault.

What happens when a fault is detected?

When a fault is detected, the FFB analyzes the data to diagnose the nature and location of the problem. It generates alarms or alerts to notify operators, allowing them to take timely corrective actions.

Does the FFB provide real-time monitoring?

Yes, the FFB provides real-time monitoring of system performance. It alerts operators to faults as they occur, enabling quick responses to prevent damage or operational disruptions.