World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

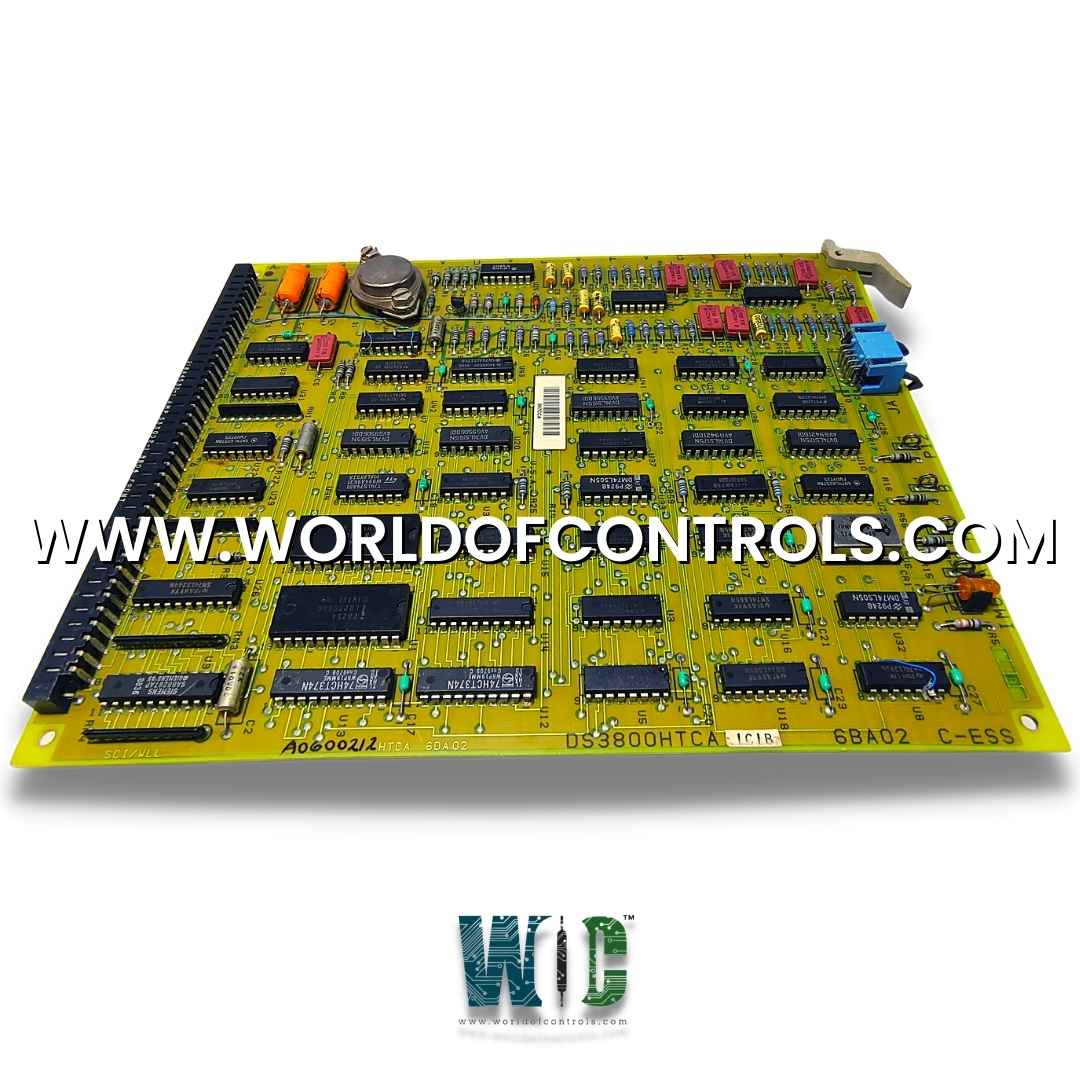

DS3800HTCA - E-Tachometer Condition Monitoring Board is available in stock which ships the same day.

DS3800HTCA - E-Tachometer Condition Monitoring Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800HTCA - E-Tachometer Condition Monitoring Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800HTCA

Manufacturer: General Electric

Series: Mark IV

Product Type: E-Tachometer Condition Monitoring Board

Number of channels: 12

Operating temperature: -30 to 65 degrees Celsius

Size: 8.25 cm high x 4.18 cm

Repair: 3-7 Day

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800HTCA is an E-Tachometer Condition Monitoring Board manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. An E-Tachometer Condition Monitoring Board is a device used for monitoring and analyzing the condition of tachometers in various applications. Tachometers are instruments used to measure the rotational speed or angular velocity of a rotating component, such as an engine shaft, motor, or turbine. The E-Tachometer Condition Monitoring Board is designed to interface with tachometers and provide real-time monitoring of their performance. It typically consists of electronic circuitry and sensors that capture data from the tachometer and transmit it to a monitoring system for analysis. The board may include features such as signal conditioning, data acquisition, and communication interfaces.

The main purpose of an E-Tachometer Condition Monitoring Board is to detect and diagnose any abnormalities or faults in the tachometer's operation. By continuously monitoring the tachometer's performance, it can identify issues such as speed variations, irregularities, or failures that may indicate potential problems with the rotating machinery it is connected.

FEATURES:

The features of an E-Tachometer Condition Monitoring Board may vary depending on the specific manufacturer and model. However, here are some common features you can expect to find in such a board:

Signal Conditioning: The board typically includes signal conditioning circuits to amplify, filter, and normalize the signals received from the tachometer. This ensures accurate and reliable measurement data for further analysis.

Data Acquisition: The board integrates data acquisition capabilities to capture and digitize the tachometer signals. It may include analog-to-digital converters (ADCs) to convert the analog signal from the tachometer into digital form for processing.

Real-time Monitoring: The board continuously monitors the tachometer's performance in real time. It measures parameters such as rotational speed, angular velocity, and frequency and provides instant feedback on the tachometer's condition.

Fault Detection and Diagnostics: The board employs algorithms and signal analysis techniques to detect abnormalities and faults in the tachometer's operation. It can identify issues like speed variations, deviations from expected values, and irregularities in the signal waveform. This enables early detection of potential problems and facilitates proactive maintenance.

Communication Interfaces: The board typically includes communication interfaces such as Ethernet, serial ports (RS-232/RS-485), or other standard industrial protocols (e.g., Modbus) to transmit the collected data to a central monitoring system or a computer for analysis and further processing.

WOC maintains the largest inventory of Replacement parts for GE Speedtronic control systems. Additionally, we offer warranty-backed unused and rebuilt boards as well as board repairs for your damaged ones. For your OEM needs, our team of professionals is available around the clock. We at WOC are happy to help you with any needs you may have in terms of automation. Please contact our team by phone or email for pricing and availability on any components and repairs.

What is the purpose of an E-Tachometer Condition Monitoring Board?

The purpose of an E-Tachometer Condition Monitoring Board is to monitor and analyze the condition of tachometers in various applications. It helps detect abnormalities or faults in the tachometer's operation and enables proactive maintenance to prevent equipment failures.

How does an E-Tachometer Condition Monitoring Board work?

The board interfaces with the tachometer and captures data from its signals. It processes the data, performs analysis, and detects any irregularities or faults. The board can communicate the collected data to a central monitoring system for further analysis and visualization.

What Payment Options Do You Accept?

Bank Transfer is the preferred payment method. For more payment options contact us.