SPECIFICATIONS

Part Number: DS3800HLOC

Manufacturer: General Electric

Series: Mark IV

Product type: Logic Output Circuit Board

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

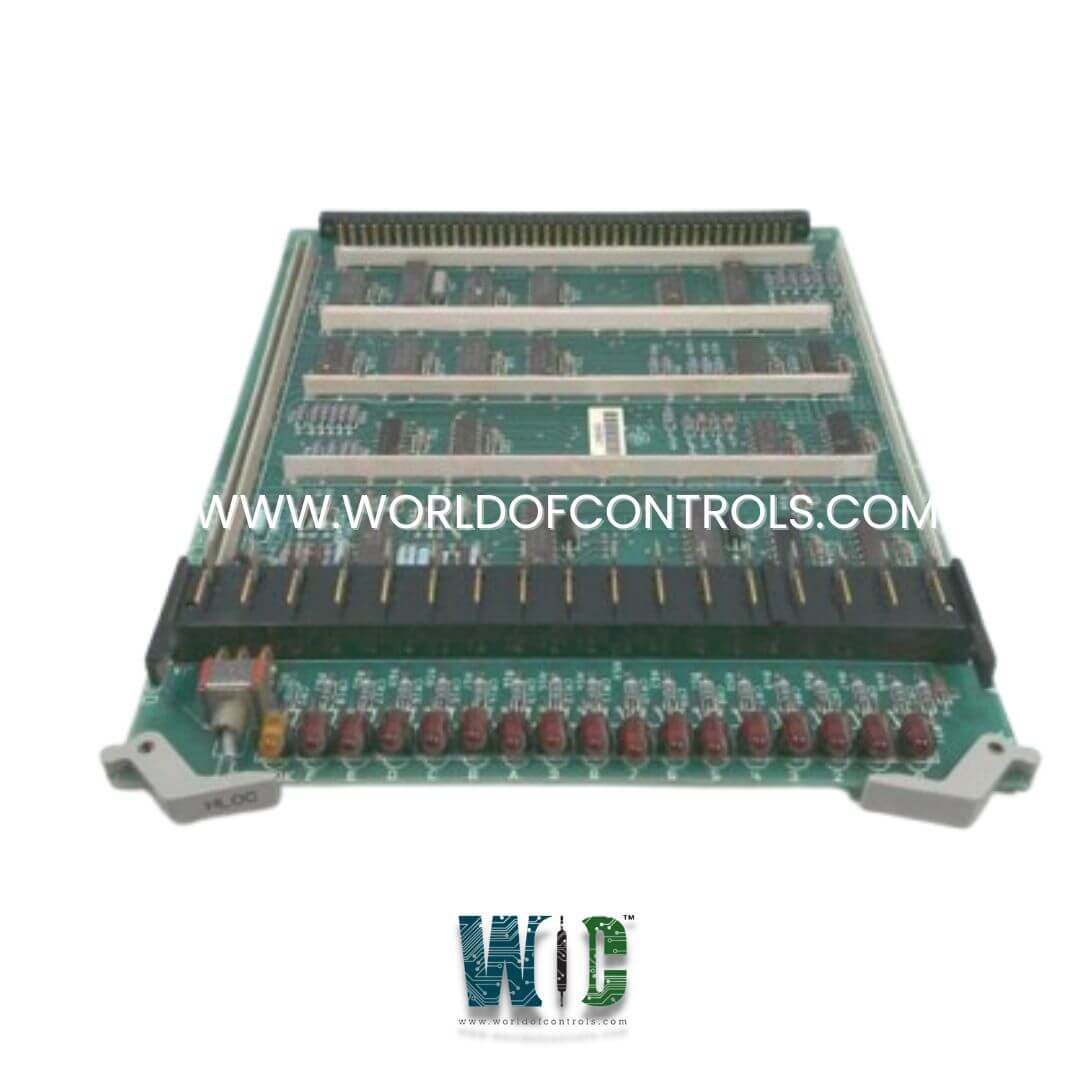

DS3800HLOC is a Logic Output circuit board developed by GE. It is a part of Mark IV control system. Specifically designed to meet the control and communication needs of the system, the component plays a crucial role in transmitting logic signals and providing visual indication through its light-emitting diodes (LEDs).

Features

- The board is meticulously crafted to cater to the intricate control and communication requisites of the system.

- Its primary function revolves around the transmission of crucial logic signals vital for system operations. Additionally, it incorporates light-emitting diodes (LEDs) to provide visual indicators, offering essential insights into the status and performance of the controlled processes.

- By intricately managing and transmitting logic signals while offering visual indications through its LEDs, the card plays an indispensable role in ensuring smooth and efficient operations within the Mark IV control system. Its precise design and functionality make it a critical asset for maintaining system integrity and facilitating effective communication within the broader control framework.

- Front-Edge LED Array: The front edge of the board is populated with multiple light-emitting diodes (LEDs) arranged in a line. This LED array serves as a visual indicator, displaying critical information regarding the logic output status. The board includes one yellow LED and sixteen red LEDs, each serving a specific purpose in the system's monitoring and control processes.

- Board Stiffeners: To ensure structural integrity and stability, it incorporates multiple board stiffeners. These stiffeners enhance the rigidity of the board, preventing any unwanted flexing or bending that may occur during operation or handling. The reinforced design helps maintain the optimal performance and reliability of the board in demanding environments.

- Rear-Edge Backplane Connector: Features a single backplane connector located on its rear edge. This connector enables seamless communication and integration with the rest of the rack and the Mark IV control system. It facilitates the exchange of logic signals and data between the board and other components within the system, ensuring coordinated control and operation.

- Rack and System Communication: Through the backplane connector, the board establishes communication links with the rack and the broader Mark IV control system. This connectivity allows for synchronized control and information exchange, enabling the board to receive commands and transmit logic signals as required by the system's operational logic and control strategy.

Product Attributes

- Digital Logic: The board includes various digital logic components, such as gates (AND, OR, XOR), flip-flops, latches, and counters. These components enable the implementation of logical operations to generate output signals based on the input commands and conditions.

- Output Signal Generation: The board generates output signals based on the logic functions and input signals received from the control system's processor or other input modules. These signals are designed to activate and control different components, devices, or actuators within the turbine system.

- Interface Compatibility: The logic output circuit board is designed to be compatible with the specific interface requirements of the turbine control system. It may support standard communication protocols or digital interfaces, such as RS-485, Ethernet, or Fieldbus protocols, to ensure seamless integration with the overall control architecture.

- Signal Conditioning: The board may include signal conditioning circuitry to ensure proper voltage, current levels, or impedance matching for the output signals. This helps in interfacing with different types of control devices or actuators effectively.

- Expandability and Customization: The circuit board may offer expansion options or customizable features to accommodate specific requirements of the turbine control system. This can include additional input/output ports, configurable logic functions, or the ability to interface with specialized control devices.

System Alarm Display

- Alarm Display Selection: The System Alarm Display can be accessed by pressing the ALARM pushbutton in the DISPLAY MODE group. Upon selection, the display shows the time and date information for up to 19 alarm messages. Additionally, it presents a system queue that can hold up to 57 messages. A new alarm message is visually indicated by flashing in inverse video and accompanied by an audible alarm, ensuring prompt attention from operators.

- Alarm Acknowledgment: To acknowledge an alarm and indicate that it has been recognized, operators can press the ALARM ACK pushbutton located to the right of the Cathode Ray Tube (CRT). Acknowledging an alarm clears it from the active alarm list, allowing operators to focus on remaining and new alarm messages.

- Alarm Group Controls: Located beneath the CRT, the ALARM group includes several pushbuttons that provide control over alarm functions. The ALARM SILENCE pushbutton allows operators to silence audible alarms temporarily. The ALARM RESET pushbutton can be used to reset the alarm system after resolving the underlying issue. These controls provide operators with essential options to manage alarms effectively.

- Alarm Review: The System Alarm Display features an ALARM REVIEW pushbutton positioned to the right of the CRT. By pressing this pushbutton, operators can cycle through the alarm messages one by one, starting from the first alarm. This functionality allows for easy navigation and review of each alarm, ensuring comprehensive awareness of the system's alarm history.

- Diagnostic Alarm Display: In addition to standard alarm messages, the System Alarm Display also includes a feature for viewing diagnostic alarm messages. By pressing the DIAGNOSTIC ALARM pushbutton located to the right of the CRT, operators can access this specific display. It presents up to 19 diagnostic alarm messages initially, with a system queue capacity of 40 messages. Similar to the standard alarm display, this display includes ALARM ACKNOWLEDGE, ALARM REVIEW, and ALARM RESET pushbuttons for efficient management of diagnostic alarms.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is DS3800HLOC?

It is a Logic Output circuit board developed by GE.

What is the backplane connector for?

The backplane connector enables the board to communicate with the rest of the rack and the Mark IV system. This is likely a critical function for the board, as it allows it to receive and transmit data or commands to other components in the system.

How can I access the System Alarm Display?

To access the System Alarm Display, simply press the ALARM pushbutton located in the DISPLAY MODE group.

What information does the System Alarm Display show?

Upon selection, the System Alarm Display presents the time and date information for up to 19 alarm messages. It also displays a system queue that can hold up to 57 messages.

How are new alarm messages indicated on the display?

New alarm messages are visually indicated by flashing in inverse video. They are also accompanied by an audible alarm to ensure prompt attention from operators.