World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS3800DMFA - Motor Field Regulator Board is available in stock which ships the same day.

DS3800DMFA - Motor Field Regulator Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800DMFA - Motor Field Regulator Board, contact us and we will get back to you within 24 hours.

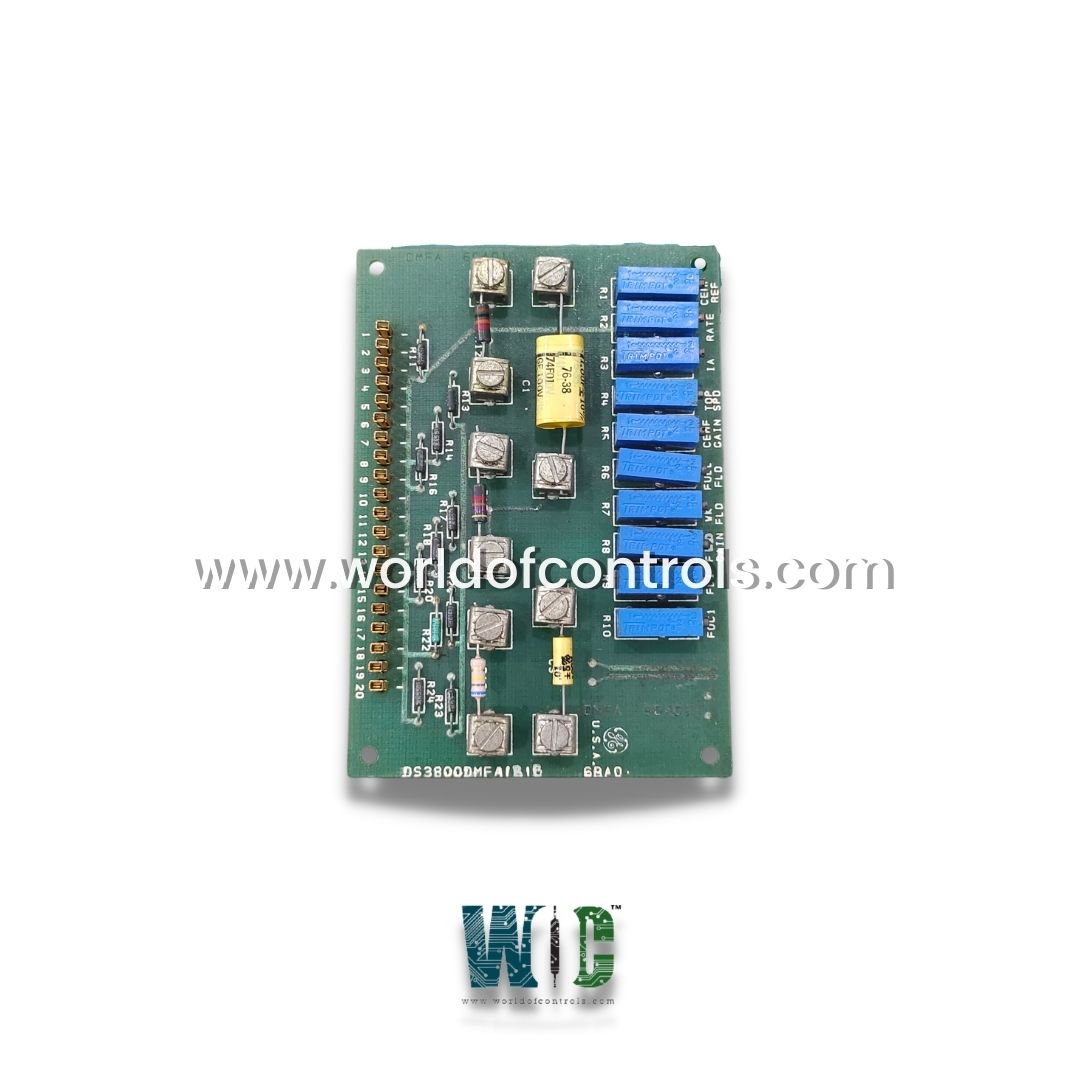

Part Number: DS3800DMFA

Manufacturer: General Electric

Series: Mark IV

Product type: Motor Field Regulator Board

Availability: In Stock

Country of Manufacture: United States (USA)

DS3800DMFA is a Motor Field Regulator Board designed and developed by GE. It is a part of Mark IV control system. It is designed to regulate and control the field current or voltage of motors. Its primary function is to fine-tune and optimize the performance of the control system. The board is responsible for adjusting and controlling the magnetic field strength around the rotor. This control over the field current or voltage allows for precise speed and torque regulation.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS3800DMFA?

It is a Motor Field Regulator Board designed and developed by GE.

Why is proper connector handling crucial when working with the board?

Proper connector handling is essential to prevent damage to the board and ensure efficient operation. Misalignment or improper handling can lead to operational issues.

How should single-pin connectors be inserted into the board?

It is important to have a clear view of both the cable and the connector, align the pin accurately with the receptor, and apply gentle, even pressure to ensure it is fully inserted for a stable electrical connection.

Why is proper cable routing important when using the board in the control system?

Proper cable routing ensures functionality and prevents potential issues. It is especially important for maintaining proper airflow, which is crucial for temperature regulation in motor control systems.