World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

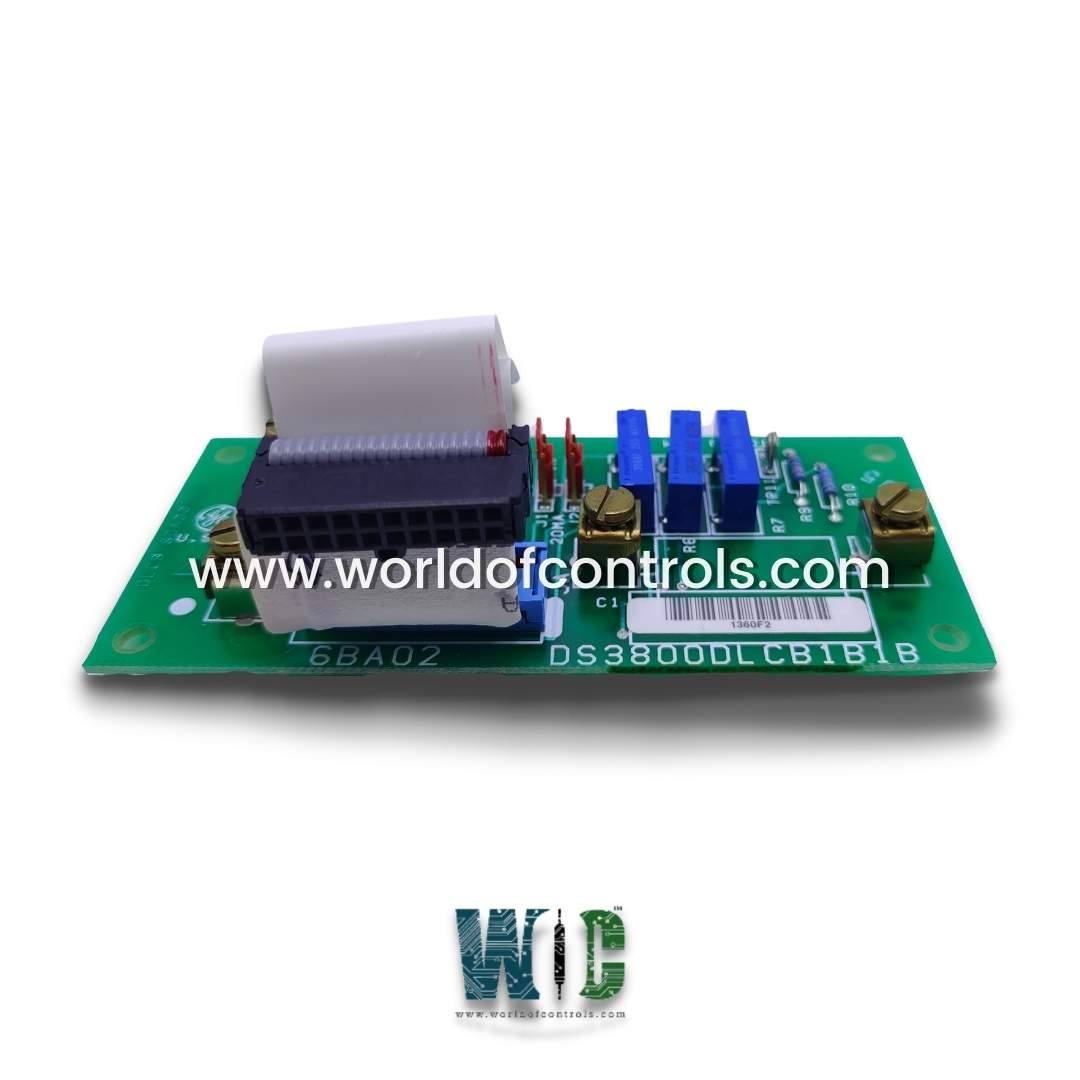

DS3800DLCB1B - Analog Daughter Board of NLCB is available in stock which ships the same day.

DS3800DLCB1B - Analog Daughter Board of NLCB comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800DLCB1B - Analog Daughter Board of NLCB, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800DLCB1B

Manufacturer: General Electric

Series: Mark IV

Product Type: Analog Daughter Board of NLCB

Signal Types: Analog signals

Number of channels: 12

Analog-to-Digital Conversion: 12-bit

Input Impedance: 10k - 100k Ohm

Operating Voltage: 5V, 12V, 24V

Current Measurement Range: 0-100A

Voltage Measurement Range: 0-250V

Signal Input Range: 0-10V

Operating temperature: -40 to 85 degrees Celsius

Response Time: 1-10ms

Size: 8.25 cm high x 4.18 cm

Repair: 3-7 Day

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800DLCB1B is an Analog Daughter Board of NLCB manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. The Analog Daughter Board of an NLCB (Network Load Control Board) typically functions as an extension or auxiliary component within a system designed for controlling electrical load, power distribution, or monitoring purposes. This daughterboard is likely used to provide analog input or output interfaces that facilitate communication with sensors, analog measurement devices, or other electrical systems. It might include components like amplifiers, signal conditioning circuits, or ADCs (Analog-to-Digital Converters), depending on its specific application.

FUNCTIONAL ANALOG DAUGHTER BOARD:

WOC maintains the largest inventory of Replacement parts for GE Speedtronic Control Systems. Additionally, we offer warranty-backed unused and rebuilt boards as well as board repairs for your damaged ones. For your OEM needs, our team of professionals is available around the clock. We at WOC are happy to help you with any needs you may have in terms of automation. Please contact our team by phone or email for pricing and availability on any components and repairs.

What is an Analog Daughter Board?

An Analog Daughter Board is a specialized circuit board that works as an extension to a primary control system like an NLCB (Network Load Control Board). It is primarily designed to handle analog signals from various sensors, such as voltage, current, and power meters, and process them into data that the main control board can use.

What are the main functions of an Analog Daughter Board in an NLCB?

The primary function of the Analog Daughter Board in an NLCB is to process analog signals. These signals can include voltage, current, and power readings, which are crucial for monitoring the electrical system. The daughterboard conditions these signals by amplifying, filtering, and adjusting them as needed. It also includes an Analog-to-Digital Converter (ADC) that converts these analog signals into digital data that can be processed by the main control system.

How does an Analog Daughter Board improve the NLCB’s performance?

An Analog Daughter Board significantly enhances the performance of the NLCB by handling the specialized task of signal processing. It ensures that the data gathered from sensors is accurately processed and presented in a usable format for the main control board. By taking care of the analog-to-digital conversion and signal conditioning, the daughterboard ensures the NLCB receives reliable and high-quality data.

What types of sensors are typically connected to the Analog Daughter Board?

The Analog Daughter Board connects to a variety of sensors that measure key electrical parameters. These can include current sensors, voltage sensors, temperature sensors, and power meters. Each of these sensors plays a role in monitoring different aspects of the electrical system. Current and voltage sensors are used to measure the flow of electricity and voltage levels, while temperature sensors can help detect overheating issues.