World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS3800DGTA - Daughter Board is available in stock which ships the same day.

DS3800DGTA - Daughter Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800DGTA - Daughter Board, contact us and we will get back to you within 24 hours.

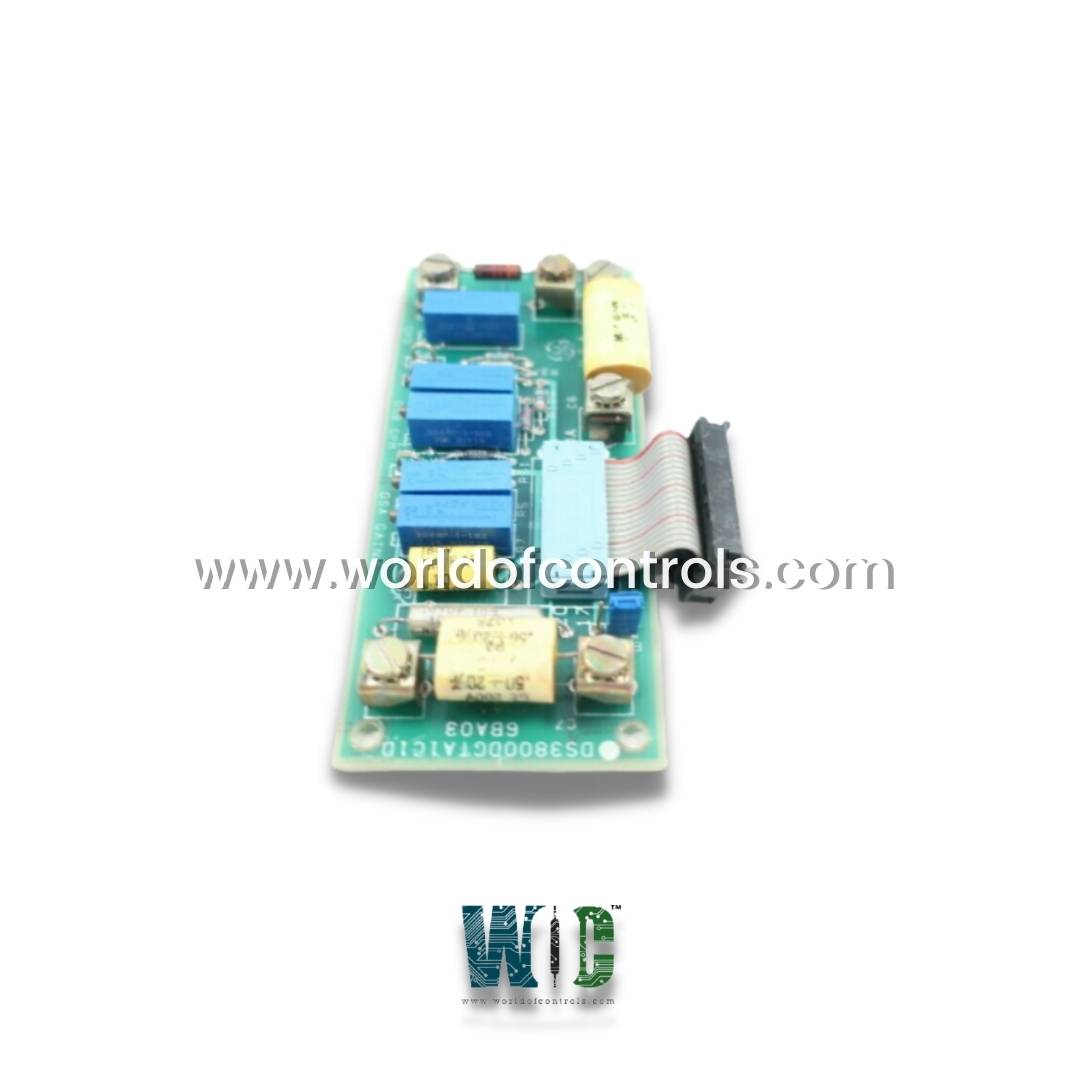

Part Number: DS3800DGTA

Manufacturer: General Electric

Series: Mark IV

Function: Daughter Board

Operating temperature: -35 to +55oC

Product Type: Power Supply

Country of Manufacture: United States (USA)

DS3800DGTA is a Daughter Board manufactured and designed by General Electrics. It is a part of the Mark IV Control System. These cards facilitate various functions, such as data acquisition from sensors that monitor critical parameters like temperature, pressure, and vibration, while also performing signal processing to ensure accurate data transmission.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS3800DGTA?

It is a Daughter Board manufactured and designed by General Electrics.

How does the membrane switch in the Operator Interface work?

The membrane switch is a modern, industrial-grade component that replaces older dedicated switches with hand wiring. When an operator presses a pad on the membrane switch, it arms the command, which is acknowledged by a flashing LED and a beep. This provides visual and audible feedback, ensuring that the operator knows the system is ready for the next step.

What happens after the arm command is given?

Once the arm command is activated, the operator must then press the execute pad to initiate the action. After executing the command, the turbine will respond, and the LED will change from flashing to a steady light, indicating that the command has been successfully processed and the turbine is carrying out the action.