World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

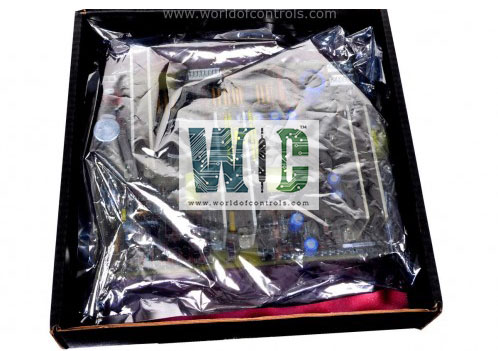

IS230TRLY1BG01 - Relay Output Assembly Module is available in stock which ships the same day.

IS230TRLY1BG01 - Relay Output Assembly Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230TRLY1BG01 - Relay Output Assembly Module, contact us and we will get back to you within 24 hours.

Part No.: IS230TRLY1BG01

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Size: 17.8 cm wide x 33.02 cm high

Temperature: -30 to + 65oC (-22 to +149 oF)

Product Type: Relay Output Assembly Module

Availability: In Stock

Series: Mark VI

IS230TRLY1BG01 is a Relay Output Assembly Module developed by GE. It is a part of Mark VI control system.

The terminal board accommodates 12 plug-in magnetic relays.

The first six relay circuits are configurable via jumpers to support either dry contact outputs, Form-C contact outputs, or to drive external solenoids.

Jumper configurations allow flexibility in adapting the relay circuits to specific application requirements.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

What is IS230TRLY1BG01?

It is a relay output assembly module developed by GE under the Mark VI series.

What are jumpers JP1-JP6, and why are they removed in the factory?

Jumpers JP1-JP6 are electrical connectors that serve various functions within the system. They are removed in the factory and shipped separately in a plastic bag as a precautionary measure. This allows for flexibility in configuring the system based on specific requirements and ensures safe transportation of the equipment.

When should jumpers be re-installed, and why?

Jumpers should be re-installed when power to a field solenoid is required. These jumpers establish the necessary electrical connections to enable the operation of field solenoids within the system.

How should jumpers be re-installed?

To re-install jumpers, carefully refer to the system documentation or schematic diagrams to determine the appropriate jumper configuration based on the specific requirements of the application. Follow standard practices for jumper installation, ensuring proper alignment and secure connections.