World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

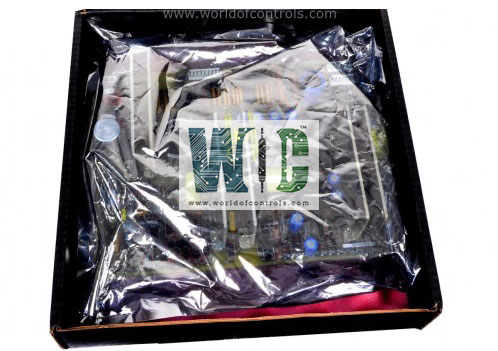

IS230TNAOH2C - TBAOH1C/PAOCH1B, Analog Output DIN Rail Module is available in stock which ships the same day.

IS230TNAOH2C - TBAOH1C/PAOCH1B, Analog Output DIN Rail Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230TNAOH2C - TBAOH1C/PAOCH1B, Analog Output DIN Rail Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS230TNAOH2C

Manufacturer: General Electric

Series: Mark VIe

Product Type: Analog Output DIN Rail Module

Internal Power Supply: 24 VDC

Resolution: 12-bit or 16-bit

Output Accuracy: ±0.1%

Output Signal Types: 0-10 V, 0-20 mA, 4-20 mA

Max Load Resistance (for 4-20 mA): 500 Ω

Power Supply: 24 V DC ±10%

Analog output current: 0-20 mA

Mounting Type: DIN Rail

Operating temperature: 4.4 to 60 °C

Size: 17.8 cm wide x 33.02 cm

Repair: 3-7 days

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IS230TNAOH2C is a TBAOH1C/PAOCH1B, Analog Output DIN Rail Module manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. It’s a compact and reliable component used in industrial automation systems to deliver analog signals to field devices such as actuators, control valves, and variable speed drives. Designed for DIN rail mounting, this module offers ease of installation within control cabinets, making it an efficient solution for modern process control applications. It typically supports standard analog output ranges such as 4-20 mA or 0-10 V, allowing smooth and accurate signal transmission to end devices.

This module is often part of a larger control system, such as a PLC (Programmable Logic Controller) or DCS (Distributed Control System), where it functions as the interface between the controller and field equipment. The naming convention—TBAOH1C and PAOCH1B—suggests that the module may be composed of two parts: the terminal block (TBAOH1C), which facilitates wiring and connectivity, and the analog output card (PAOCH1B) that handles the signal processing and output functions.

INSTALLATION:

The TBAOH1C/PAOCH1B Analog Output Module is designed for DIN rail mounting, which allows for quick and secure installation inside electrical panels or control enclosures. The module typically consists of two parts: the TBAOH1C terminal base and the PAOCH1B analog output card. During installation, the terminal base is first mounted on the DIN rail and securely latched into place. Field wiring is then connected to the terminal points on the TBAOH1C, which are clearly labeled to identify each analog output channel, power supply, and ground terminals. Once the wiring is complete, the PAOCH1B card is plugged into the terminal base, ensuring proper alignment and connection.

OPERATIONS:

The PAOCH1B module functions as a high-precision analog signal generator that translates digital control signals from the turbine controller into analog signals, typically 4–20 mA current loops or 0–10 V voltage signals. These signals are crucial for operating proportional devices like fuel control valves, hydraulic actuators, and steam inlet control systems. In a turbine control loop, the controller calculates the desired output (based on feedback like turbine speed, temperature, or load) and sends a digital command to the PAOCH1B. The module then converts this command into a smooth, noise-immune analog output. Redundancy and diagnostic features are typically built into the system to detect open circuits, output faults, or calibration drift, triggering alarms or switching to backup paths.

WOC has the largest stock of OEM Replacement Parts for GE Distributed Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is the resolution of the analog output signals?

The module offers 12-bit or 16-bit resolution, depending on the specific version. This allows for fine-grained control over the analog outputs, with up to 65536 discrete levels for each channel in a 16-bit configuration.

What is the maximum load capacity for the current output channels?

The maximum load resistance for 4-20 mA and 0-20 mA output typically ranges from 500 Ω to 1000 Ω, depending on the output voltage. The module can support a 500-ohm load at 20 mA current output.

What communication protocols are supported by the module?

The module supports Modbus RTU (over RS-485) and Profibus protocols for communication with a PLC or DCS. Some versions may also support Ethernet-based protocols such as Ethernet/IP or Profinet.