World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

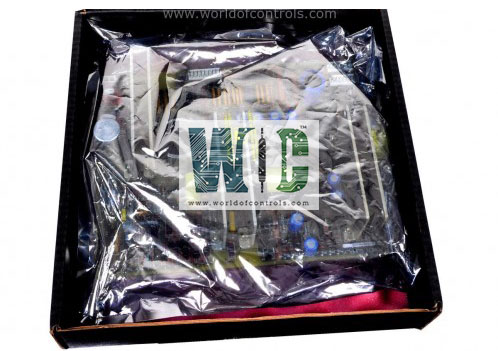

IS230TEFV1AG01 - Electric Fuel Valve Gateway Interface Module is available in stock which ships the same day.

IS230TEFV1AG01 - Electric Fuel Valve Gateway Interface Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230TEFV1AG01 - Electric Fuel Valve Gateway Interface Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS230TEFV1AG01

Manufacturer: General Electric

Series: Mark VIe

Number of Channels: 24

Microprocessor: Intel Celeron 650 MHz

Memory: 128 MB SDRAM

Product Type: Electric Fuel Valve Gateway Interface Module

Maximum Lead Resistance: 15 Ω

Operating temperature: 0 to 60° C

Technology: Surface mount

Size: 15.9 cm high x 10.2 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

Manual: GEH6421D

FUNCTIONAL DESCRIPTION:

IS230TEFV1AG01 is an Electric Fuel Valve Gateway Interface Module manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The Electric Fuel Valve Gateway (TEFV) is an Ethernet gateway linking the Mark VIe I/O Ethernet network with an electric fuel valve interface module. This module, the Digital Valve Positioner (DVP), is produced by Woodward Controls and communicates via Ethernet Global Data (EGD). The TEFV features a standard processor board across all Mark VIe I/O packs. It includes dual RJ45 Ethernet connectors: one connects to the I/O Ethernet network, while the other connects directly to the DVP. Additionally, a 3-pin connector is provided for powering the pack.

OPERATION:

The Electric Fuel Valve Terminal board (TEFVH1A), in this configuration, is used to mount the TEFV only. The connections on the board are for electronic ID only. It uses no other connections. Visual diagnostics are provided through indicator LEDs on the TEFV. An infrared port provides local diagnostic serial communication. The processor board in the pack is common to all Mark VIe Ethernet I/O packs. It contains the following:

INSTALLATION:

To securely mount the TEFVH1A terminal board, first ensure it is securely fastened. Next, plug in three PEFVs to the terminal board connectors for triple modular redundancy (TMR). Mechanically secure the packs using the threaded inserts located next to the Ethernet ports; these inserts connect to a mounting bracket that is specific to the terminal board type. It’s important to adjust the bracket to avoid applying right-angle force to the DC-37 pin connector between the pack and the terminal board, which only needs to be done once during the product's lifespan.

After securing the packs, plug one Ethernet cable into the I/O Ethernet network and connect the other cable to the corresponding network connector on the Woodward DVP. The pack can operate with connections made to either port, but a reboot is required if the connections are modified. Standard practice is to connect ENET1 to the I/O Ethernet network. Power should be applied to the connector on the side of the pack; it is not necessary to remove power from the cable while inserting the connector, as the PEFV includes an inherent soft-start capability that manages current inrush upon power application. Finally, configure the PEFV as needed.

WOC has the largest stock of OEM Replacement Parts for GE Distributed Turbine Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How do I secure the TEFV to the terminal board?

Use the threaded inserts adjacent to the Ethernet ports to mechanically secure the packs to a mounting bracket specific to the terminal board type.

Do I need to adjust the mounting bracket?

Yes, the bracket should be adjusted to ensure no right-angle force is applied to the DC-37 pin connector between the pack and the terminal board. This adjustment only needs to be done once.

How do I connect the Ethernet cables?

Plug one Ethernet cable into the I/O Ethernet network and the other into the corresponding network connector on the Woodward DVP. The pack will function with connections made to either port.