World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS230TCSAH1A - Fuel Skid Interface Board is available in stock which ships the same day.

IS230TCSAH1A - Fuel Skid Interface Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230TCSAH1A - Fuel Skid Interface Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

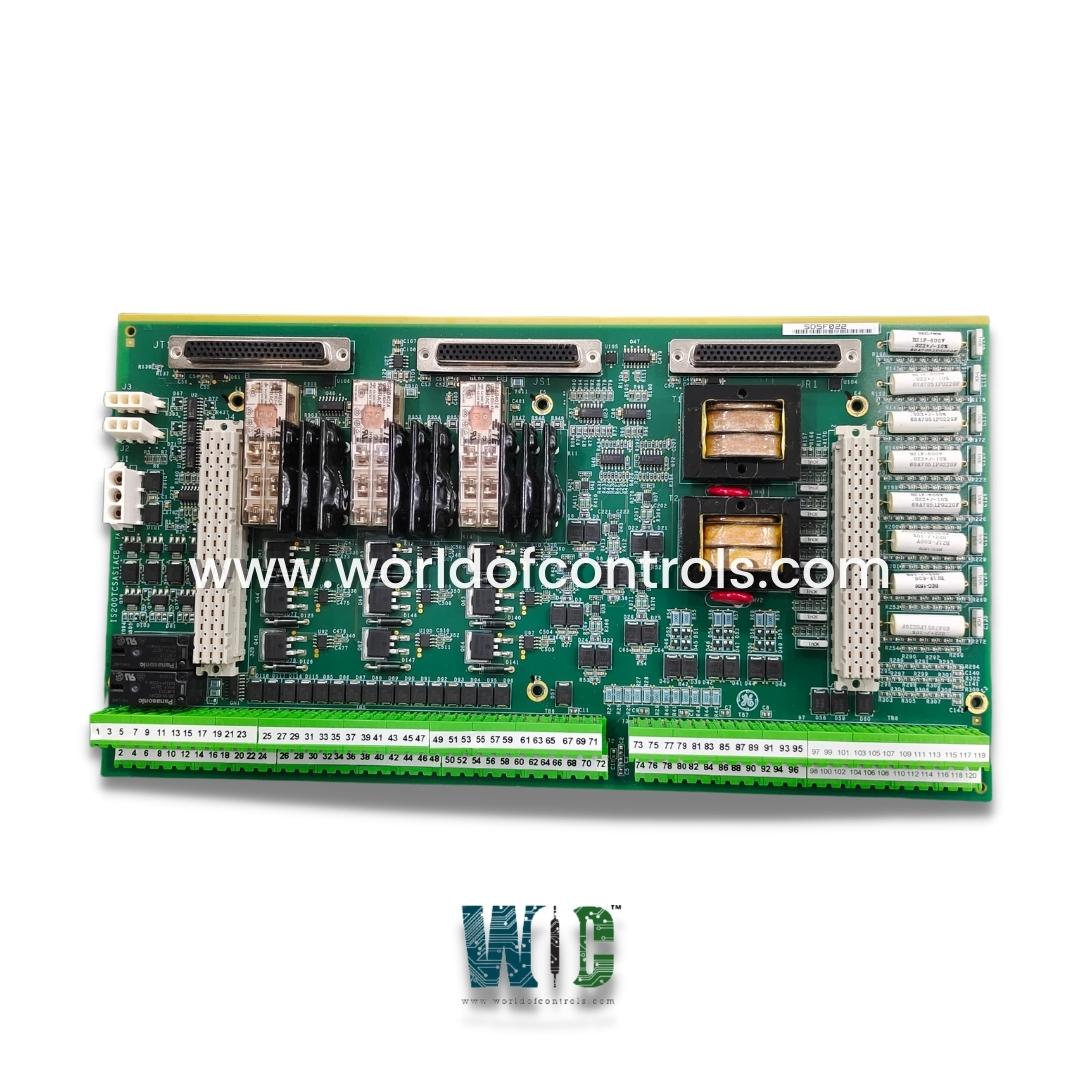

Part No.: IS230TCSAH1A

Manufacturer: General Electric

Product Type: Fuel Skid Interface Board

Series: Mark VIeS

Output Voltage Ratings: 24V DC

Safety Standards: SIL 2

Mounting Type: Rack-mounted

Communication: Tricon Communication Module

Operating Temperature: -40°C to +70°C

Availability: In Stock

Size: 17.8 cm wide x 33.02 cm

Country of Manufacture: United States

Manual: GEH-6723P

FUNCTIONAL DESCRIPTION:

IS230TCSAH1A is a Fuel Skid Interface Board manufactured and designed by General Electric and is part of the Mark VIeS Series used in GE Distributed turbine control systems. The Fuel Skid Interface Board (TCSA), located in

TCSA PRESSURE TRANSDUCER INTERFACE:

The TCSA board signals are read from the pressure transducers by the XDSA board on the fuel skid. The signals from the XDSA board are sent to the TBSA terminal board, which transfers them to the TCSA board over the P3 connector. The TCSA board decodes the RS422 protocol signals and writes them to the UCIB board for processing by the 196 processor. The TCSA board also provides the power for the pressure transducers and FMVED motor controllers.

WOC has the largest stock of Replacement Parts for GE Distributed turbine control systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly contact our team by phone or email.

What are the main functions of a Fuel Skid Interface Board?

The Fuel Skid Interface Board performs several important functions, such as collecting data from sensors that monitor fuel flow, temperature, and pressure. It communicates with control systems to regulate the operation of the fuel skid unit, ensuring it operates efficiently and safely.

What types of sensors are connected to the Fuel Skid Interface Board?

The Fuel Skid Interface Board connects to a range of sensors that monitor critical aspects of the fuel system. These typically include flow meters to measure the rate of fuel flow, pressure sensors to ensure the system operates within safe pressure levels, temperature sensors to prevent overheating of the fuel, and leak detection sensors for identifying any potential fuel spills or leaks in the system.

How does the Fuel Skid Interface Board communicate with the central control system?

The Fuel Skid Interface Board communicates with the central control system through various industrial communication protocols, such as Modbus, Ethernet/IP, or other recognized standards. This allows for seamless data transmission, including real-time updates on system performance, which helps operators monitor and adjust the system as needed.