World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

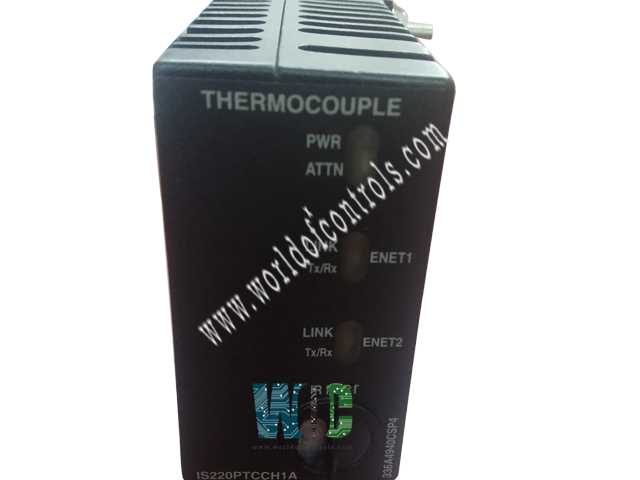

IS220PTCCH1A, REV G - Thermocouple Input Module is available in stock which ships the same day.

IS220PTCCH1A, REV G - Thermocouple Input Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS220PTCCH1A, REV G - Thermocouple Input Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS220PTCCH1A, REV G

Manufacturer: General Electric

Series: Mark VIe

Function: Thermocouple Input Module

Number of Channels: 12

Thermocouple Types: E, J, K, S

Span: -8 mV to +45 mV

A/D Converter: 16-bit

Common Mode Voltage: +5 Volts

Normal Mode Rejection: 250mV

Microprocessor: AMD-K6 300 MHz

Operating temperature: -30 to 65 °C

Size: 8.26 cm wide x 4.19 cm

Technology: Surface Mount

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

Manual: GEH-6721D

FUNCTIONAL DESCRIPTION:

IS220PTCCH1A, REV G is a Thermocouple Input Module manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The PTCC serves as the electrical interface between one or two I/O Ethernet networks and a thermocouple input terminal board. It includes a processor board that is shared across all Mark VIe distributed I/O packs and an acquisition board dedicated to the thermocouple input functionality. The pack supports up to 12 thermocouple inputs, and when two packs are used, it can handle up to 24 inputs on TBTCH1C. In a TMR configuration with the TBTCH1B terminal board, three packs are required, each with its cold junction, but only 12 thermocouples are supported. The pack receives input via dual RJ45 Ethernet connectors and a three-pin power input. The output is through a DC-37 pin connector that directly connects to the terminal board. Visual diagnostics are indicated through LEDs, and local diagnostics can be accessed via an infrared port.

INSTALLATION:

OPERATION:

ANALOG INPUT HARDWARE:

The PTCC input board receives 12 millivolt-level signals from the thermocouples connected to the terminal board. The analog input system includes six differential multiplexers, a main multiplexer, and a 16-bit analog-to-digital converter that transmits the digital data to the processor board. Each input is equipped with hardware and firmware filters, and the converter samples at a rate of up to 120 Hz.

WOC has the largest stock of replacement parts for GE Distributed Turbine Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly contact our team by phone or email.

What is the purpose of the Thermocouple Input Module?

The Thermocouple Input Module interfaces with thermocouples to measure temperature and converts the analog signals into digital data for processing. It connects to the terminal board and communicates with the processor board for further data handling.

How many thermocouple inputs can the module handle?

The module can handle up to 12 thermocouple inputs. In some configurations, two modules can support up to 24 inputs, and three modules can be used in a TMR configuration with the TBTCH1B terminal board, though only 12 thermocouples are supported.

What types of thermocouples are supported by the module?

The module is designed to work with various types of thermocouples, typically including standard types like J, K, T, and others. It is important to ensure compatibility with the specific thermocouple type used.