World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

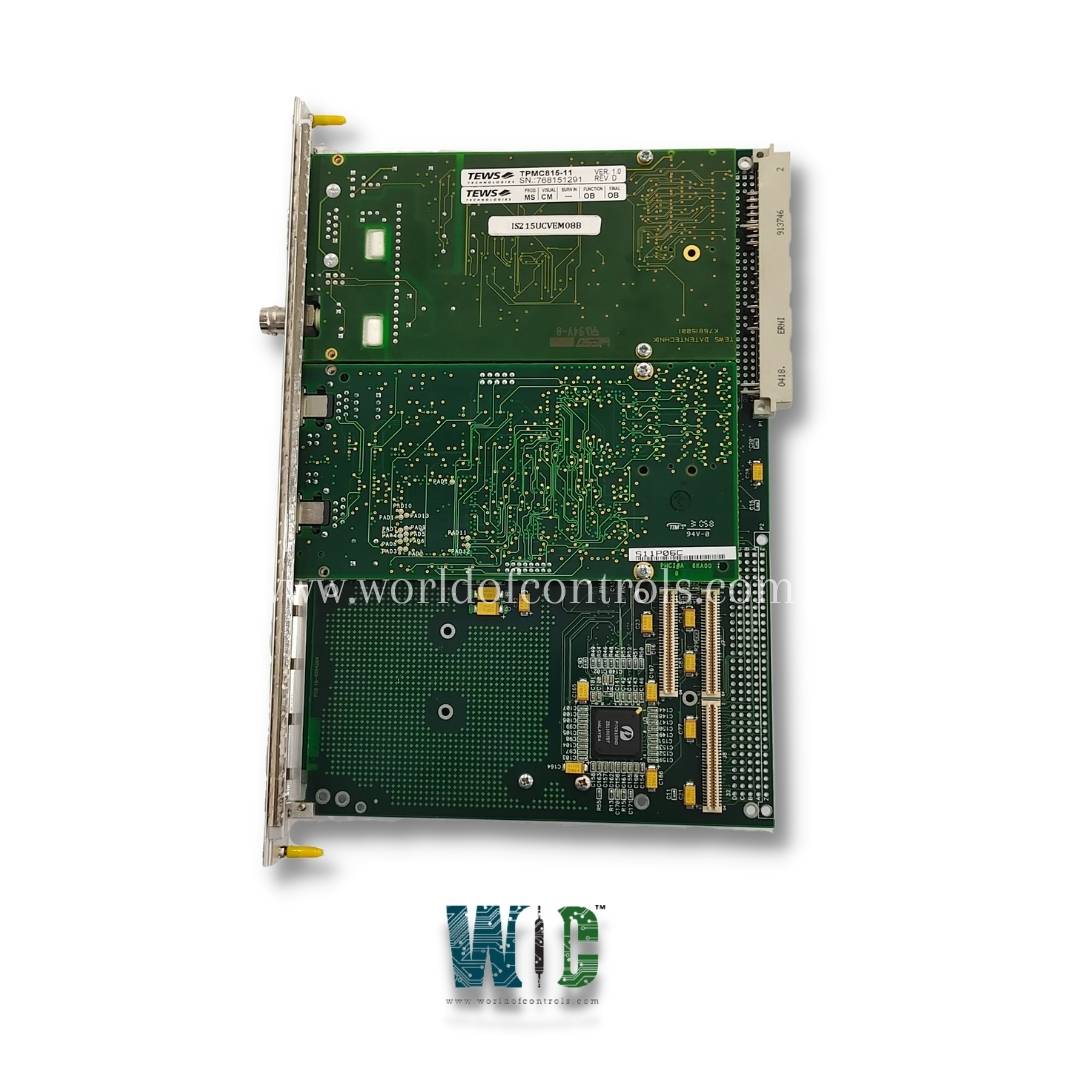

IS215UCVEM08B - US2000 Processor Board is available in stock which ships the same day.

IS215UCVEM08B - US2000 Processor Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS215UCVEM08B - US2000 Processor Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS215UCVEM08B

Manufacturer: General Electric

Series: Mark VI

Product Type: US2000 Processor Board

Number of channels: 12

Operating System: QNX

Microprocessor: Intel Celeron 300 MHz

Technology: Surface Mount

Programming: Control block

Common Mode Voltage Range: +5 V dc

Maximum Lead Resistance: 15Ω

Analog output current: 0-20 mA

Operating temperature: -30 to 65 °C

Size: 8.26 cm high x 4.18 cm

Repair: 3-7 Day

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IS215UCVEM08B is a US2000 Processor Board manufactured and designed by General Electric as part of the Mark VI Series used in GE Speedtronic Gas turbine Control Systems. In the context of turbine control systems, a processor board typically refers to a printed circuit board (PCB) that contains a microprocessor or microcontroller responsible for executing control algorithms and managing the overall operation of the turbine. These boards are a critical component of the control system, handling tasks such as data acquisition, signal processing, and control logic implementation. Processor boards in turbine control systems often have specialized features to meet the specific requirements of the application. They may include inputs and outputs for sensor and actuator interfacing, communication interfaces for integration with other control components, and support for real-time operations.

FEATURES:

Processor boards used in turbine control systems typically possess several key features to ensure reliable and efficient operation. While the exact specifications may vary based on the specific application and manufacturer, here are some common features:

Microprocessor or Microcontroller: The processor board incorporates a high-performance microprocessor or microcontroller capable of executing control algorithms and handling data processing tasks.

Real-Time Operation: Turbine control systems require a real-time operation to respond to dynamic conditions promptly. Processor boards are designed to provide fast and deterministic processing, enabling real-time control and decision-making.

Input/Output (I/O) Interfaces: The board includes multiple I/O interfaces to connect with various sensors and actuators in the turbine system. These interfaces facilitate data acquisition from sensors and the activation of actuators for precise control.

Communication Interfaces: Processor boards often have communication interfaces to exchange data with other control systems components, such as Human-Machine Interfaces (HMIs), supervisory systems, or remote monitoring systems. Common communication protocols include Ethernet, Modbus, Profibus, CAN bus, etc.

Diagnostic and Monitoring Capabilities: Processor boards often include diagnostic and monitoring features to facilitate system troubleshooting and maintenance. These capabilities enable monitoring of board health, sensor readings, actuator status, and other operational parameters.

WOC has the largest stock of GE Speedtronic Gas Turbine Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

FREQUENTLY ASKED QUESTIONS:

What is the role of a processor board in a turbine control system?

A processor board is a critical component that houses a microprocessor or microcontroller responsible for executing control algorithms, managing data acquisition from sensors, processing signals, and implementing control logic in a turbine control system.

What are the key benefits of using a processor board in turbine control systems?

Processor boards offer real-time operation, precise control, and reliable performance in turbine control systems. They enable efficient data processing, seamless integration with other control system components, and the execution of complex control algorithms.

How is redundancy achieved in processor boards for turbine control systems?

Redundancy in processor boards can be achieved through the use of redundant processors or processor cores. These redundant components operate in parallel, allowing for fault tolerance and automatic failover in case of a failure in one of the processors.