World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

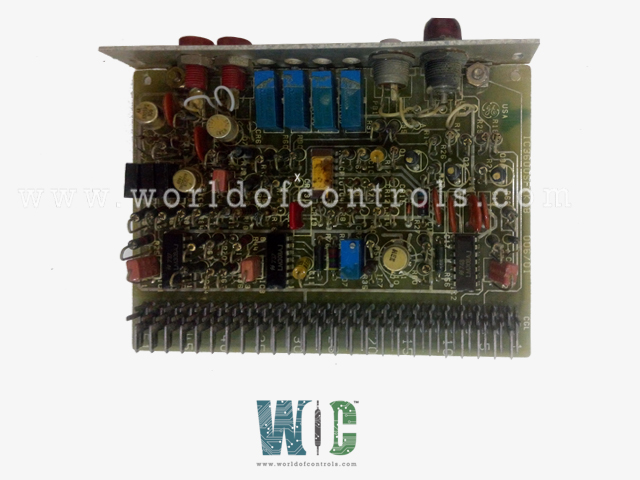

IC3600SFKK1 - Fuel Valve Control Board is available in stock which ships the same day.

IC3600SFKK1 - Fuel Valve Control Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IC3600SFKK1 - Fuel Valve Control Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: IC3600SFKK1

Manufacturer: General Electric

Product Type: Fuel Valve Control Board

Series: Mark II

Operating temperature: -40 to 70 ºC

Input DC voltage: +24V

Power Consumption: 10-30W

Input Signals: 0-24V

Power Supply Voltage: 24 V dc

Board Size: 2.8 cm high x 8.6 cm

Weight: 0.45 kg

Availability: In Stock

Country of Origin: USA

FUNCTIONAL DESCRIPTION:

IC3600SFKK1 is a Fuel Valve Control Board manufactured and designed by General Electric as part of the Mark II Series used in GE Speedtronic Control Systems. the Fuel Valve Control Board is a crucial component responsible for regulating the flow of fuel into the turbine's combustion chamber. By ensuring precise fuel delivery, it optimizes turbine efficiency, power output, and emissions control. The board works by receiving data from various sensors—such as pressure, temperature, and flow rate sensors—and uses this information to adjust the position of the fuel valves. It sends signals to actuators, which open or close the valves accordingly, based on real-time turbine load and operational conditions.

FUNCTIONS:

WOC has the largest stock of OEM replacement parts for GE Speedtronic Gas Turbine Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a Fuel Valve Control Board?

A Fuel Valve Control Board is a critical component in turbine control systems that regulates the flow of fuel to the combustion chamber. It ensures optimal fuel delivery based on the turbine’s real-time operational needs, improving efficiency and performance.

How does the Fuel Valve Control Board optimize fuel flow?

The control board uses real-time data from sensors (such as pressure, temperature, and flow sensors) to adjust the fuel valves. Modulating the valve position ensures the right amount of fuel is delivered for efficient combustion under varying load conditions.

What safety features does the Fuel Valve Control Board have?

It monitors key parameters like fuel pressure, flow rate, and temperature. If abnormal conditions, such as high pressure or fuel blockages, are detected, the board can initiate safety protocols like an emergency shutdown to prevent turbine damage or unsafe conditions.