SPECIFICATIONS

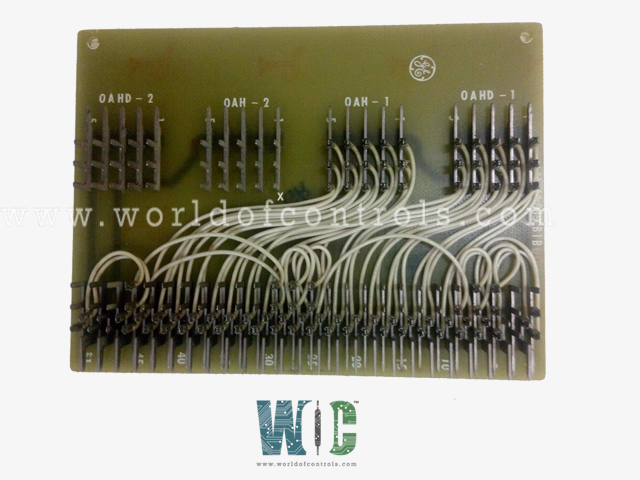

Part No: IC3600QIXB60

Manufacturer: General Electric

Function: Jumper Card

Series: Mark I and II

Repair: 3-7 Day

Availability: In Stock

Country of Manufacturer: United States (USA)

Functional Description

IC3600QIXB60 is a Jumper Card developed by GE. It is a part of Mark I and II control system. These Jumper Cards are instrumental in enhancing the efficiency, reliability, and performance of the system. This module plays a critical role in connecting and configuring components within the control system, facilitating seamless communication and ensuring the proper operation of various control functions.

Features

- The Jumper Card serves to establish electrical connections between different circuit boards and components in the control system. It allows configuration changes and connections to be made easily by inserting or removing jumpers to adjust parameters.

- It is designed to be used specifically within GE Speedtronic systems, where it is integrated into the control panel for configuring communication and operational logic between modules.

- The card features multiple jumper pins and is typically used in conjunction with other control system components, allowing for various adjustments and configurations based on system requirements.

System Start-Up

- Start-up Control Loop: The start-up control loop within the turbine control panel is responsible for initiating the turbine's operation. It ensures a smooth and controlled start-up process. This is essential to prevent abrupt changes in power generation and to protect the turbine from sudden stress. During this phase, the control system operates as an open-loop system, setting predefined fuel levels to the turbine as it begins to spin.

- Load, Speed, and Temperature Control Loops: These control loops are responsible for the continuous and dynamic management of the turbine's performance. The load control loop adjusts the turbine's power output to match the required load, ensuring that it operates efficiently. The speed control loop maintains the turbine's rotational speed within specified limits, which is crucial for stability and the prevention of over-speed conditions. The temperature control loop is essential for managing the temperature of critical components, helping to prevent overheating and potential damage.

- Variable Control Electrons (VCE): VCE serves as a key reference signal for the fuel control loops. By modulating VCE, the fuel control system can precisely adjust the flow of fuel to the turbine. This is a critical aspect of controlling power output and ensuring the turbine operates within safe and efficient limits.

- Nozzle Control Electrons (NCE): In the case of two-shaft turbines, such as in some gas turbines, the nozzle control loop modulates NCE to control the high-pressure (H.P.) shaft's speed. This precise control is crucial for optimizing performance and managing the power generation process effectively.

- Sequential Control Circuitry: The sequential control circuitry works in tandem with the start-up control loop to ensure that the turbine operates in a controlled sequence. It prevents premature or abrupt changes in fuel flow and power output during the start-up phase, promoting a safe and stable transition to full operation.

- Setting Limits: The start-up control loop also plays a role in defining the minimum and maximum limits on VCE after the initial start-up period. These limits are crucial for maintaining the turbine's operational integrity and safety. They prevent excessive fluctuations in fuel flow, power output, and temperature, which could lead to equipment stress and damage.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is IC3600QIXB60?

It is a Jumper Card developed by GE

What is the role of the start-up control loop in a turbine control panel?

The start-up control loop initiates the turbine's operation, ensuring a controlled start-up process. It sets predefined fuel levels and operates as an open-loop system during this phase to protect the turbine.

How do load, speed, and temperature control loops contribute to turbine operation?

Load control loop adjusts the turbine's power output, speed control loop maintains rotational speed, and temperature control loop manages component temperature to ensure efficient and safe turbine operation.

How does sequential control circuitry work with the start-up control loop?

Sequential control circuitry coordinates with the start-up control loop to ensure a controlled sequence of operations, preventing sudden changes in fuel flow and power output during start-up.