World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

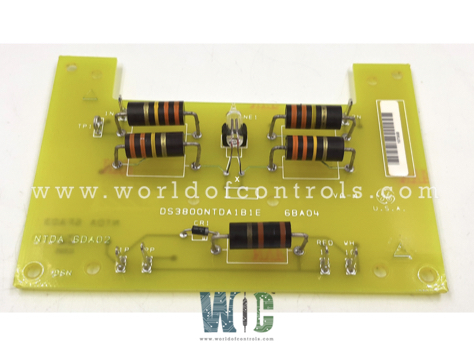

DS3800NTDA1B1E - Control Display Digital Card is available in stock which ships the same day.

DS3800NTDA1B1E - Control Display Digital Card comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NTDA1B1E - Control Display Digital Card, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS3800NTDA1B1E

Manufacturer: General Electric

Series: Mark IV

Product Type: Control Display Digital Card

Power Requirements: +5 V dc

Power Supply Voltage: 24 V dc

Operating Temperature: -35 to +55°C

Size: 15.7 cm high x 18.5 cm

Weight: 0.5kg

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS3800NTDA1B1E is a Control Display Digital Card manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. A Control Display Digital Card is a crucial component in modern control systems, especially within applications like turbine control systems. It primarily serves the function of converting real-time data from various sensors into digital signals, which can then be processed and displayed to operators. The card typically receives inputs in the form of analog signals, such as temperature, pressure, vibration, and speed, from sensors monitoring the turbine's performance.

These analog signals are then digitized, enabling the system to monitor and control the turbine's operation more efficiently. These systems allow for automated adjustments and precise control of the turbine based on the data from the display card. The integration ensures a seamless flow of information and helps maintain optimal performance. The card also serves as a user interface, enabling operators to interact with the turbine system, adjust settings, and troubleshoot any issues directly from the control display.

TYPES OF CONTROL DISPLAY DIGITAL CARDS:

HOW CONTROL DISPLAY DIGITAL CARDS WORKS:

WOC has the largest stock of GE Speedtronic Gas Turbine Control Systems Replacement Parts. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a Control Display Digital Card?

A Control Display Digital Card is an electronic component used in control systems to process and display real-time data. In turbine control systems, it converts input data from sensors (like temperature, pressure, and speed) into digital signals that can be displayed on control panels for operators to monitor.

How does a Control Display Digital Card work?

The card receives analog signals from various sensors monitoring the turbine, such as temperature, pressure, and vibration. It converts these signals into digital data and drives the visual display, allowing operators to monitor key turbine parameters in real-time. It may also trigger alarms or alerts if any readings exceed safe limits.

What parameters does the Control Display Digital Card monitor?

The card typically monitors key turbine parameters like turbine speed, temperature, pressure, vibration levels, and flow rate. These metrics are displayed in real-time to help operators track turbine performance.