SPECIFICATIONS

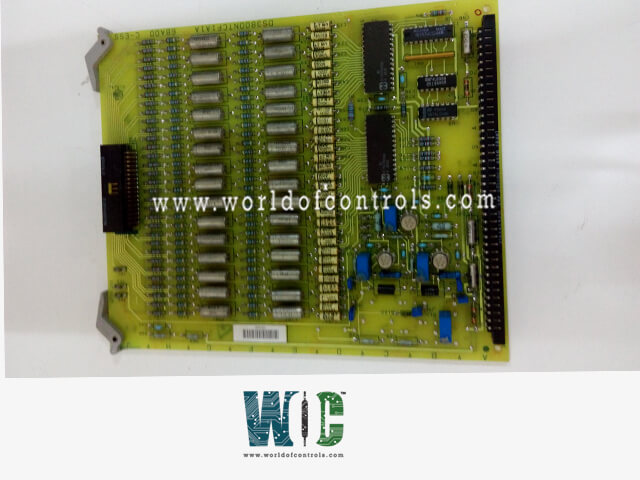

Part No.: DS3800NTCF1C1C

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Product Type: Thermocouple Condition Card

Availability: In Stock

Series: Mark IV

Functional Description

DS3800NTCF1C1C is a Thermocouple Condition Card developed by GE. It is a part of the Mark IV control system. This card is specifically designed to monitor and regulate the exhaust temperature in turbine systems, ensuring optimal performance and preventing potential damage due to temperature imbalances.

Features

- Exhaust Temperature Monitoring: The card reads real-time exhaust temperature data from thermocouples installed in the turbine system. This information is essential for assessing the operating conditions of the turbine and maintaining thermal balance.

- Temperature Difference Calculation: The card computes the difference between the actual exhaust temperature and a pre-set reference temperature. This calculated difference serves as a command signal to adjust turbine parameters and maintain the desired exhaust temperature.

- Statistical Temperature Control: The Mark IV control system uses thirteen cards to provide statistical accuracy and redundancy in temperature control. The collective data ensures precise exhaust temperature regulation, which is crucial for preventing issues such as overheating or inefficiency.

- Fault Prevention: Corrupt data from any of the thermocouple cards can result in poor statistical input, potentially causing combustor or engine issues. Proper maintenance and monitoring of these cards are vital to ensuring system health and operational reliability.

- Advanced PCB Connectivity: The card includes two PCB connectors - 218A4637-P4, 218A4553-1 Amp 533002-1. These ensure reliable communication with the control system.

Built-in Diagnostic Points: Two lines of test points (TP) provide convenient access for diagnostics. One line with three test points. Another line with four test points.

Durable Construction: Designed for the demanding environments of power generation and industrial applications, the card is built with high-quality components to ensure long-term reliability.

Maintenance

- Inspection: Regularly check for physical wear, corrosion, or damage.

- Calibration: Ensure accurate readings through periodic calibration.

- Proactive Repairs: Address malfunctions promptly to prevent operational disruptions.

Advantages

- Precision: Provides accurate temperature monitoring and adjustments.

- Redundancy: Multiple cards reduce the risk of a single point of failure.

- Ease of Diagnostics: Test points simplify troubleshooting and maintenance.

- Reliability: Robust design ensures consistent performance in harsh environments.

The WOC team is always available to help you with your Mark IV requirements. For more information, please contact WOC.

Frequently Asked Questions

What is DS3800NTCF1C1C?

It is a Thermocouple Condition Card developed by GE under the Mark IV series.

How does the board function?

It reads the real-time exhaust temperature data from thermocouples installed in the turbine system. It computes the difference between the actual exhaust temperature and a pre-set reference temperature. This difference acts as a command signal to adjust the turbine’s parameters and maintain optimal temperature.

What could happen if one of these cards fails?

If a card provides corrupt data, it may lead to inaccurate statistical input, causing temperature mismanagement. This can result in combustor issues, engine inefficiencies, or even damage to the turbine system.