World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

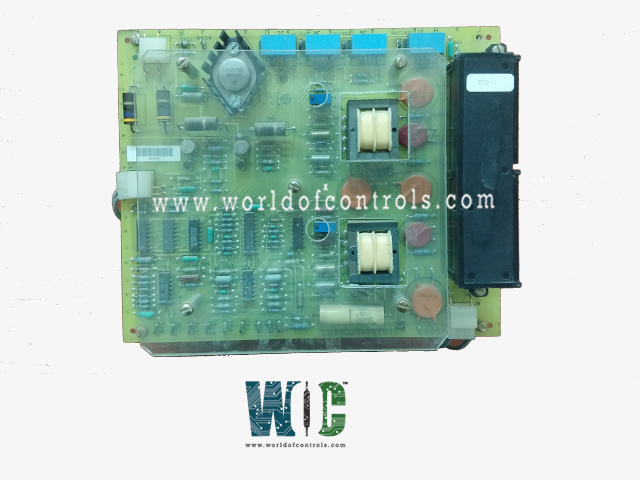

DS3800NASB1B - Analog Synchronization Isolator Board is available in stock which ships the same day.

DS3800NASB1B - Analog Synchronization Isolator Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800NASB1B - Analog Synchronization Isolator Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No: DS3800NASB1B

Manufacturer: General Electric

Series: Mark IV

Product Type: Analog Synchronization Isolator Board

Number of Channels: 8

Power Requirements: 24V DC,

Insulation Resistance: ≥ 100MΩ

Input Current: 5mA to 20mA

Output Range: 0-10 V, 4-20 mA

Dimensions: 150 mm x 100 mm x 30 mm

Mounting: Standard mounting

Operating Temperature: -40°C to +85°C

Country of Origin: USA

Availability: In Stock

FUNCTIONAL DESCRIPTION:

DS3800NASB1B is an Analog Synchronization Isolator Board manufactured and designed by General Electric and is part of the Mark IV Series used in GE Speedtronic gas turbine control systems. Its primary functions include signal isolation, conditioning, and synchronization, which are essential for ensuring the reliability and accuracy of data from various sensors used in monitoring parameters like temperature, pressure, and speed. The board effectively isolates electrical circuits to prevent interference and ground loops, protecting sensitive components from voltage spikes. It processes incoming analog signals through amplification and filtering to remove noise, ensuring clarity and reliability.

FUNCTIONS:

Signal Isolation: The Signal Isolation function of the Analog Synchronization Isolator Board (ASI Board) is crucial for maintaining data integrity in turbine control systems. By isolating different electrical circuits, it prevents ground loops and interference that can lead to erroneous readings. This protection is essential in industrial environments where electrical noise is common, ensuring that signals processed are clean and accurate for reliable turbine operation.

Signal Conditioning: It enhances the quality and reliability of incoming analog signals from various sensors. This process includes amplification to boost weak signals, filtering to eliminate unwanted noise, and linearization to convert non-linear outputs into a more interpretable form. By conditioning signals effectively, the ASI Board ensures precise monitoring and control of critical turbine parameters, such as temperature and pressure.

Signal Synchronization: Its function ensures that multiple signals from different sensors are temporally aligned, which is vital for accurate data analysis. This alignment prevents discrepancies in the data collected from various turbine parameters being monitored simultaneously. By synchronizing signals, the ASI Board enhances the control system's ability to respond in real time, maintaining optimal performance and safety in turbine operations.

Data Transmission: Once signals are processed, the ASI Board's Data Transmission function sends the refined and synchronized signals to the main control system, like a PLC or HMI. This timely transmission is essential for enabling effective decision-making and operational control. By ensuring that accurate data reaches the control system, the ASI Board facilitates immediate responses to changing conditions within the turbine, thereby enhancing overall operational efficiency.

Diagnostic Capabilities: The Diagnostic Capabilities of the ASI Board are vital for ensuring the reliability and longevity of turbine control systems. Equipped with continuous monitoring tools, the board assesses its health and performance in real-time. By identifying faults early, these diagnostics provide alerts for maintenance, helping to minimize downtime and enhance the overall reliability of the turbine operation.

Integration with Control Systems: The ASI Board's design allows for seamless Integration with Control Systems, ensuring compatibility with various turbine setups, particularly those from General Electric. Its modular design supports easy upgrades and replacements without extensive system overhauls, enhancing operational flexibility. By integrating effectively, the ASI Board contributes to optimized turbine performance in diverse industrial applications.

WOC has the largest stock of OEM replacement parts for GE Speedtronic Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is the purpose of the Analog Synchronization Isolator Board?

The ASI Board is designed to isolate, condition, synchronize, and transmit analog signals from various sensors in turbine control systems. It ensures data integrity and reliability by preventing electrical interference and processing signals for accurate monitoring and control of turbine parameters.

How does the ASI Board isolate signals?

The ASI Board isolates signals by separating different electrical circuits, which helps to prevent ground loops and electrical noise that can distort sensor readings. This isolation is essential for maintaining accurate data in environments with significant electrical interference.

What types of signals does the ASI Board process?

The ASI Board processes various analog signals, including those from temperature, pressure, and flow sensors. It amplifies weak signals, filters out noise, and linearizes non-linear outputs to ensure high-quality data is sent to the control system.