World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS3800HSAA1P1J - Servo Amplifier Board is available in stock which ships the same day.

DS3800HSAA1P1J - Servo Amplifier Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800HSAA1P1J - Servo Amplifier Board, contact us and we will get back to you within 24 hours.

Part No.: DS3800HSAA1P1J

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Product Type: Servo Amplifier Board

Availability: In Stock

Series: Mark IV

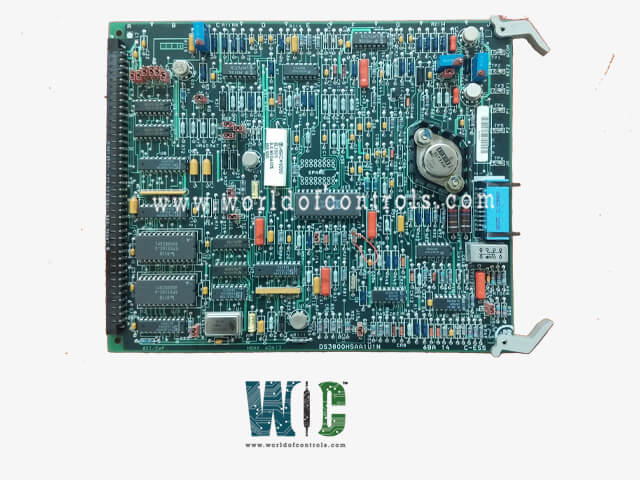

DS3800HSAA1P1J is a Servo Amplifier Board developed by GE. It is a part of the Mark IV control system. It is designed to control and amplify signals for servo motors or servo valves with high precision. It receives input signals, often analog or digital, from a control system, processes them, and drives the corresponding servo device. The board supports feedback mechanisms, such as encoders or pressure sensors, ensuring accurate closed-loop control.

The WOC team is always available to help you with your Mark IV requirements. For more information, please contact WOC.

What is DS3800HSAA1P1J?

It is a Servo Amplifier Board developed by GE under the Mark IV series.

How do I adjust the trimmer resistors?

The trimmer resistors can be adjusted using a screwdriver to fine-tune specific operational parameters. This should be done before installation to ensure the board performs optimally within the system.

What is the function of the EEPROM socket?

The EEPROM socket allows you to insert electrically erasable programmable read-only memory modules, which are used to store configuration data or firmware, providing the board with necessary operational information.

What happens if the heat sink is not working properly?

If the heat sink becomes obstructed or is not functioning correctly, the board may overheat, leading to performance degradation or system failure. Ensure that airflow is unobstructed and monitor the board for temperature spikes during operation.