World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS3800DOWE - Auxiliary Control Board is available in stock which ships the same day.

DS3800DOWE - Auxiliary Control Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS3800DOWE - Auxiliary Control Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

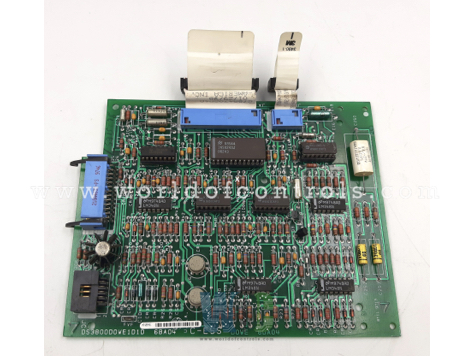

Part Number: DS3800DOWE

Manufacturer: General Electric

Series: Mark IV

Product Type: Auxiliary Control Board

Board Size: 14.75 cm High x 17.5 cm

Repair: 3-7 Days

Weight: 2.00 lbs

Country of Origin: USA

Availability: In Stock

FUNCTIONAL DESCRIPTION:

DS3800DOWE is an Auxiliary Control Board manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic turbine control systems. The AUX board is a VME-based, 6U-sized PCB board that produces all auxiliary signals and power voltages for a cluster of four flips. For the ELMB motherboard, the ELMB board itself, and the StartUp voltage for LV bricks, the board consists of a 4 x 3 independent power supply. An Auxiliary Control Board (ACB) is an essential component in various industrial and commercial applications, serving as a secondary control panel that complements the main control system. It enhances the management and monitoring of processes and equipment by providing supplementary control capabilities.

This board is crucial for maintaining redundancy, ensuring continuous operation in the event of main system failure, and enhancing safety with additional control points for emergency shutdowns and safety interlocks. Customizable to specific requirements, the ACB integrates specialized sensors and controls, making it versatile for diverse applications. In industrial plants, it manages machinery and processes, while in power generation, it controls turbines and generators. It's also vital in building automation for managing HVAC systems and utilities and in transportation for controlling subsystems in railways, ships, and aircraft. Key components of an ACB include switches, buttons, indicators, relays, communication modules, and power supplies, all of which contribute to its functionality. The ACB improves reliability through backup control capabilities, enhances safety with additional monitoring options, provides operational flexibility, and simplifies maintenance. Overall, the Auxiliary Control Board is indispensable for the smooth and safe operation of modern industrial and commercial infrastructure.

WOC has the largest stock of OEM replacement parts for GE Speedtronic Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How does an Auxiliary Control Board improve system reliability?

An ACB provides redundancy by serving as a backup control system. If the main control system fails, the ACB ensures continuous operation, preventing downtime and maintaining system reliability.

What are the key components of an Auxiliary Control Board?

Key components of an ACB include switches, buttons, indicators, displays, relays, contactors, communication modules, and power supplies. These components work together to provide comprehensive control and monitoring capabilities.

What is the role of monitoring in an Auxiliary Control Board?

Monitoring is a crucial function of an ACB, allowing for real-time tracking of parameters such as temperature, pressure, and voltage. This helps maintain optimal operational conditions and early detection of anomalies.