World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

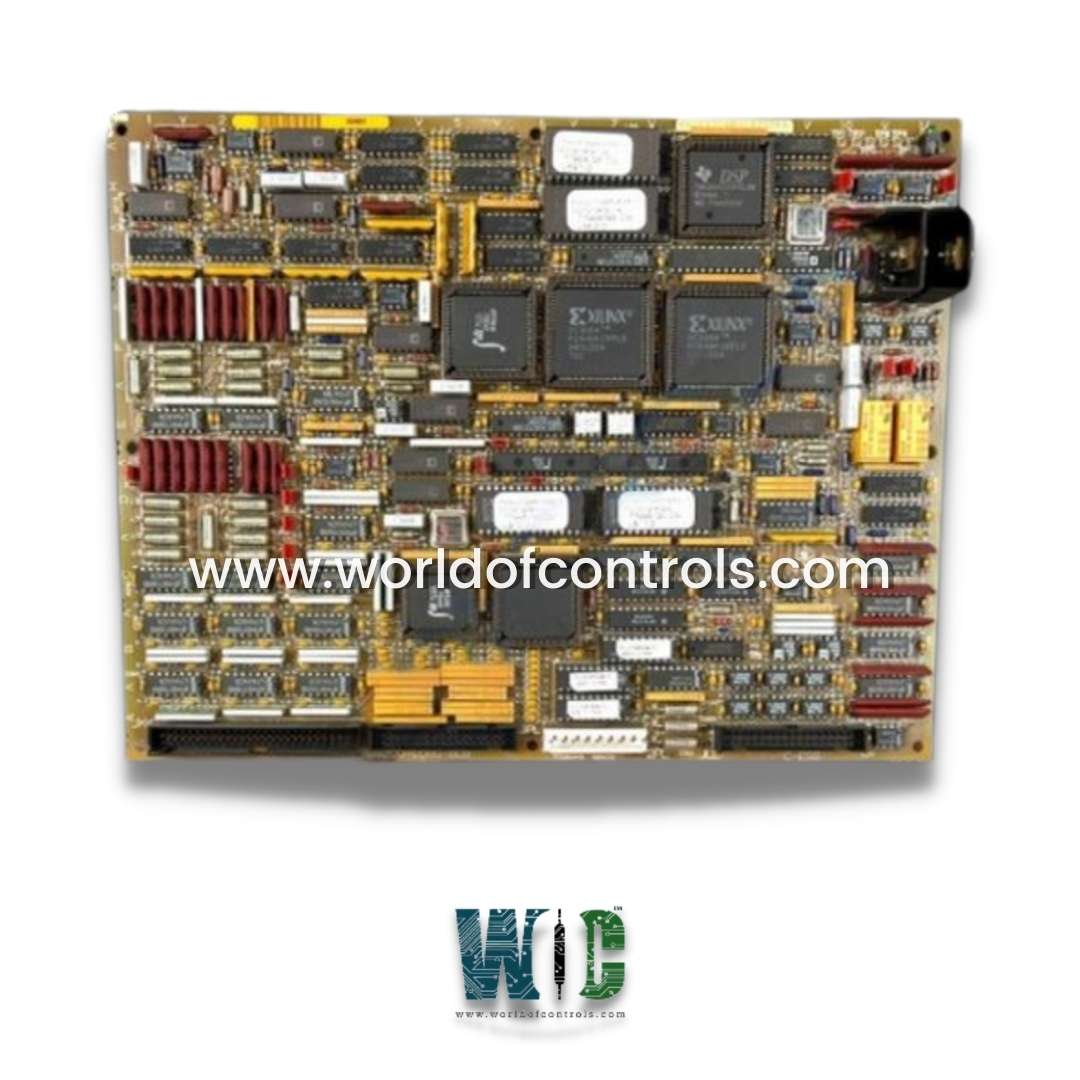

DS215TCQBG1BZZ01A - I/O Extender Board with EPROM is available in stock which ships the same day.

DS215TCQBG1BZZ01A - I/O Extender Board with EPROM comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS215TCQBG1BZZ01A - I/O Extender Board with EPROM, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS215TCQBG1BZZ01A

Manufacturer: General Electric

Series: Mark V

Product Type: I/O Extender Board with EPROM

Number of channels: 12

Input span: 4-20 mA

Bandwidth: 40 MBps

Addressing Range: 16 and 32-bits

Technology: Surface Mount

Common Mode Voltage Range: ±5 V

Maximum Lead Resistance: 15Ω

Analog output current: 0-20 mA

Operating temperature: -30 to 65 °C

Size: 8.26 cm high x 4.19 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS215TCQBG1BZZ01A is an I/O Extender Board with EPROM manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Gas Turbine Control Systems. An I/O extender board with EPROM (Erasable Programmable Read-Only Memory) is a hardware device that provides additional input/output (I/O) capabilities and includes an EPROM chip for storing program instructions or data. Here's a general overview of how such a board could be designed and used:

Hardware Design:

Microcontroller: The board would typically have a microcontroller as the main processing unit. It could be an 8-bit, 16-bit, or 32-bit microcontroller, depending on the desired complexity and performance requirements.

I/O Ports: The microcontroller would have a limited number of built-in I/O pins, so the extender board would include additional I/O ports. These ports can be general-purpose input/output (GPIO) pins or specialized interfaces like UART, SPI, I2C, etc., depending on the intended applications.

EPROM Chip: The board would integrate an EPROM chip, which is a non-volatile memory that can be electrically programmed and erased. The EPROM would provide storage for program instructions or data that can be accessed by the microcontroller.

Address Decoding: The extender board would include address decoding circuitry to enable the microcontroller to interface with the EPROM and access its contents.

P power Supply and Connectivity: The board would require a power supply, typically 5V or 3.3V, and may include connectors or headers for connecting to external devices or systems.

Programming the EPROM:

EPROM Programming Device: To program the EPROM, you would need an EPROM programmer, a specialized hardware device used to write data to the EPROM chip. The programmer is connected to a computer and allows you to transfer the desired program instructions or data to the EPROM.

EPROM Programming Software: The EPROM programmer would come with software that enables you to select the EPROM chip model, load the program or data files, and initiate the programming process. The software communicates with the programmer to transfer the data to the EPROM.

Using the I/O Extender Board:

Once the EPROM is programmed with the desired instructions or data, you can connect the I/O extender board to a target system or project.

The microcontroller on the board can read the instructions or data from the EPROM and perform the necessary operations accordingly.

The additional I/O ports provided by the extender board can be used to interface with external devices, sensors, actuators, or other components as required by your application.

WOC has the largest stock of GE Speedtronic Distributed Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

FREQUENTLY ASKED QUESTIONS:

What is the purpose of an I/O extender board with EPROM?

The purpose of an I/O extender board with EPROM is to expand the input/output capabilities of a microcontroller-based system while also providing storage for program instructions or data using the EPROM chip.

Why use an EPROM instead of other types of memory?

EPROMs offer non-volatile storage, meaning the data remains intact even when power is removed. This makes EPROMs suitable for storing program code or data that needs to be retained even after a power cycle or system reset.

How does the microcontroller access the EPROM data?

The microcontroller communicates with the EPROM using address and data lines. The address lines are used to specify the memory location to read from or write to, and the data lines carry the actual data between the microcontroller and the EPROM.