SPECIFICATIONS

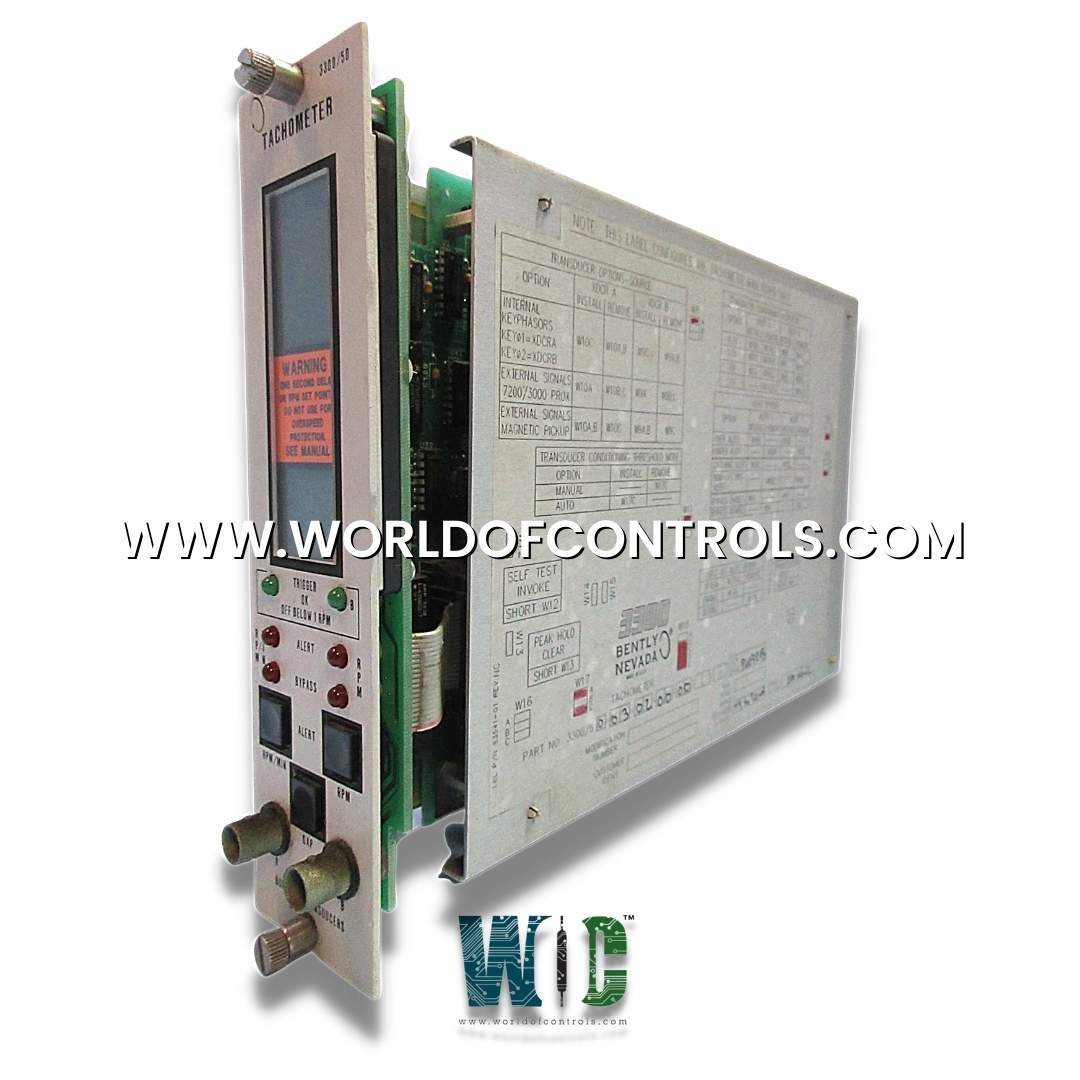

Part No.: 3300/50

Manufacturer: Bently Nevada

Product Type: Condition Monitoring Tachometer

Operating Temperature: 0 to +65 degrees Celsius

Storage Temperature: -40 to +85 degrees Celsius

Relative Humidity: To 95%, noncondensing.

Output Impedance: 100 ohm

Availability: In Stock

Series: 3300 Series

Country of Manufacture: United States (USA)

Functional Description

3300/50 is a Condition Monitoring Tachometer developed by Bently Nevada. It is a part of 3300 Bently Nevada Series. It measures shaft rotative speed, rotative acceleration, and provides an output for zero speed indication in real time. The tachometer outputs a proportional voltage or current on the back terminal strip and provides Alert status via relay contacts for use with an external annunciator panel. The Tachometer, despite being a single channel monitor, accepts input from two transducers. The monitor handles the voting logic between the two transducers, reducing false indications in the event of a single transducer failure.

3300/50 Features

- Designed to provide specific functionalities within a larger context, but it's important to note that it is not intended for use as a standalone unit or as part of a speed control or overspeed protection system. While it holds distinctive features that cater to certain requirements, it's crucial to understand its limitations and its intended use within the broader industrial landscape.

- It is not equipped with the characteristics required for accurate speed control or robust overspeed protection. These applications demand high levels of precision, responsiveness, and redundancy, which may not be fulfilled by the tachometers.

- If an analog proportional output is provided, it should be understood that this output is suitable solely for purposes such as data logging or chart recording. It may not meet the stringent requirements demanded by dynamic speed control or overspeed protection systems.

- In cases where the component provides speed alert setpoints, it's important to recognize that these setpoints serve the purpose of annunciation, rather than active control or protection. They are meant to alert operators or maintenance personnel to speed deviations.

- The message emphasized in the description underscores the significance of adhering to the designated use cases and limitations. Failure to heed these warnings and using the component beyond its intended purpose can lead to product misuse, which in turn may result in property damage and bodily injury.

- When the necessity for machine overspeed protection arises, it is advised to utilize Bently Nevada Electronic Overspeed Detection Monitors. These monitors are specifically engineered to provide the required levels of accuracy, reliability, and responsiveness for safeguarding against overspeed conditions.

Product Attributes

- Shaft Rotative Speed and Acceleration Measurement: A core feature of the product is its ability to accurately measure both the rotative speed and acceleration of a shaft. This capacity enables it to provide dynamic insights into the movement and behavior of the machinery it is monitoring.

- Output for Indicating Zero Speed: The product is designed to provide an output that specifically indicates zero speed. This capability is invaluable for recognizing instances where the machinery comes to a complete halt, aiding in operational analysis and ensuring safe handling procedures.

- Proportional Voltage Output: On its rear terminal strip, the product offers a proportional voltage output. This output can be harnessed for various purposes, including data recording, charting, and interfacing with other components of the control or monitoring system.

- Rotor Acceleration Tachometer: Positioned as a rotor acceleration tachometer, the product excels in providing insights into the rate of change in speed. This functionality is particularly useful for assessing acceleration profiles and identifying any abnormal or potentially hazardous speed changes.

- Epoxy-Sealed Alert Relay: The product features an epoxy-sealed alert relay, indicating a high degree of protection and resilience against environmental factors such as moisture, dust, and other contaminants. This ensures that the product maintains its operational integrity even in demanding conditions.

- No Agency Approval Option: It's worth noting that the product does not come with agency approval as a standard feature. This might entail that additional steps or processes might be required to align the product with specific industry or regulatory standards, depending on the intended use and regulatory requirements.

- No Safety Barrier Option: Similar to the agency approval attribute, the product lacks a safety barrier option as part of its standard features. This suggests that, if needed, the integration of safety barriers would need to be considered separately in line with the safety requirements of the operating environment.

Alarms

Alarm Setpoints:

- All alarm setpoints can be adjusted digitally. Tamper proof switches on the monitor circuit board and up/down switches on the System Monitor front panel are used to adjust them. Users can adjust the rpm and delta rpm/min alarms from 0 to 100% of the fullscale display.

- At any speed less than 100 rpm, Zero Speed Alert can be selected (and changed). Nonvolatile memory is used to store alarm setpoints.

Alarms and OK Relay Drives:

- Two Alarm relay drive signals and one OK relay drive signal.

Monitor Alarm Functions:

- Both alarm signals are field adjustable and selectable for overspeed or underspeed annunciation, as well as latching or nonlatching operation.

Alarm Time Delays:

- Rotor Acceleration or Tachometer Tachometer: whichever is greater, one second or three valid input triggers. Three valid input triggers for Zero Speed (100rpm).

- When three input triggers are not detected, an Alarm must be declared within one minute (machine rotor at zero rpm). To enable alarm detection, one valid pulse after power up is required.

System Compatibility

- The 50 mm probe is available in three case and thread configurations, allowing it to physically replace all standard 7200 50 mm systems (including side and rear exit probes). As accessories, the standard 7200 style mounting brackets are still available.

- A new bracket is also available to adapt the probe to the 50 mm DE Integral transducer sliding mount base. The Proximitor Sensor has the same 0.394 V/mm (10 mV/mil) output as the 7200 and 50 mm DE Integral systems, allowing customers to upgrade without changing the monitor configuration.

- Every transducer system component (probe, extension cable, and Proximitor Sensor) must be replaced with 50 mm components when upgrading from previous systems.

World of Controls has the most comprehensive collection of Bently Nevada products. Please contact WOC as soon as possible if you require any extra information.

�

Frequently Asked Questions

�

What is 3300/50?

It is a Condition Monitoring Tachometer developed by Bently Nevada

What is the operating temperature range?

The operating temperature range is 0 to +65 degrees Celsius.

What is the storage temperature range for the tachometer?

The storage temperature range is -40 to +85 degrees Celsius.

What is the maximum relative humidity that the product can withstand?

The tachometer can withstand relative humidity up to 95%, noncondensing.

What is the output impedance of the tachometer?

The output impedance is 100 ohm.