World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

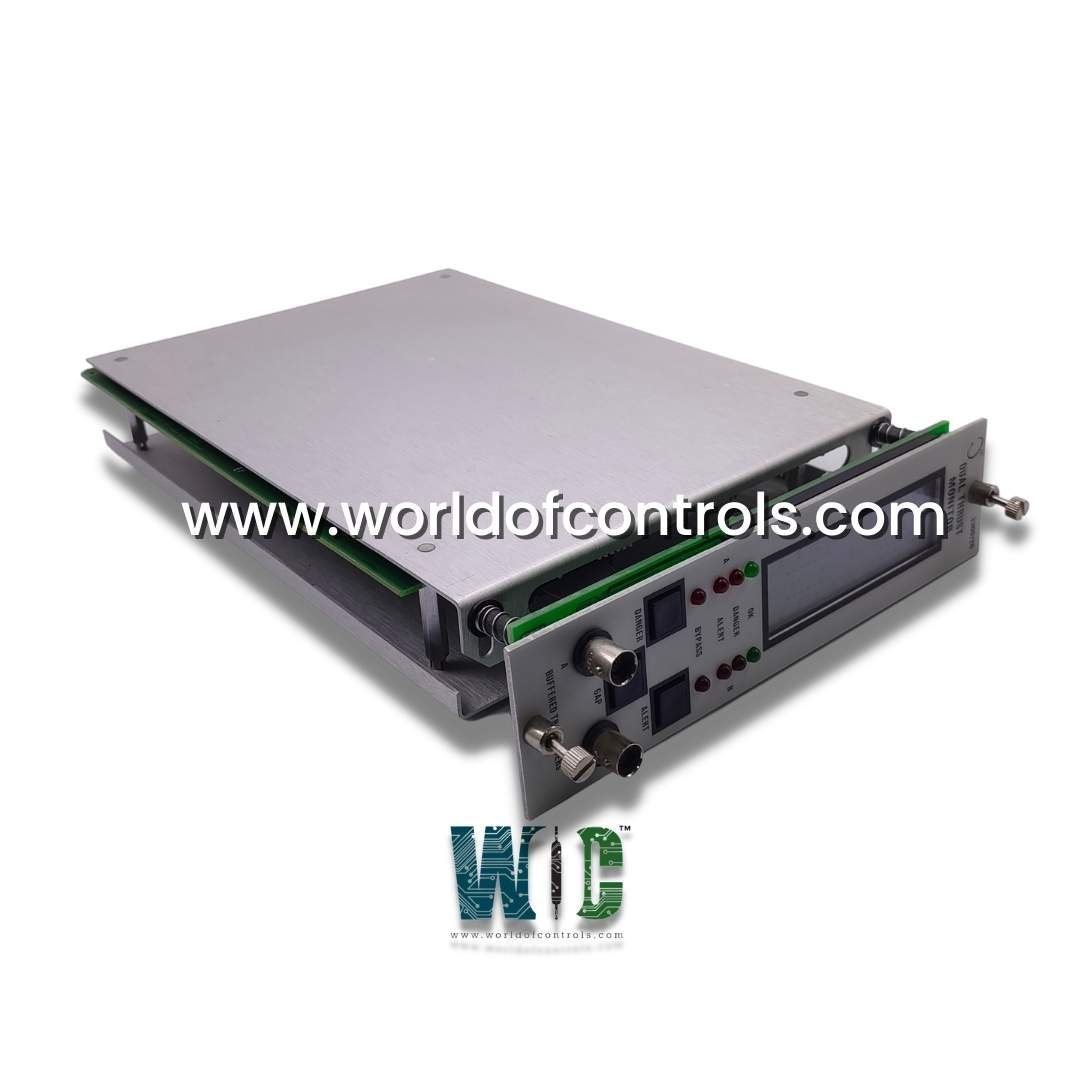

135313-01 - Dual Vibration Monitor is available in stock which ships the same day.

135313-01 - Dual Vibration Monitor comes in UNUSED as well as REBUILT condition.

To avail our best deals for 135313-01 - Dual Vibration Monitor, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: 135313-01

Manufacturer: Bently Nevada

Series: 3300/20

Product Type: Dual Vibration Monitor

Input Impedance: 10k Ohm

Sensitivity: 100 mV/mil (4 V/mm)

Power Consumption: 7.7 Watts

Signal Conditioning Accuracy: ±1% maximum

Output Impedance (voltage outputs): 100 Ohm

Voltage Compliance (current outputs): 0 to +12 Vdc

Gap Alarm Time Delay: 6 seconds

Shaft Power Supply: -24V DC

Operating Temperature: 0°C to +65°C

Power Supply Voltage: 125 V dc

Technology: Surface Mount

Size: 83 mm

Repair: 3-7 Day

Availability: In Stock

Weight: 1 Kg

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

135313-01 is a Dual Vibration Monitor manufactured and designed by Bently Nevada as part of the 3300/20 Series used to control the machinery condition monitoring system. The primary function of the 3300/20 Dual Vibration Monitor is to measure the vibration of rotating shafts and provide real-time data for condition monitoring. By continuously tracking vibration levels, it helps identify early signs of mechanical faults such as bearing wear, imbalance, shaft misalignment, and mechanical looseness. The monitor is designed to receive input from two independent vibration transducers, such as proximity probes or velocity sensors, allowing simultaneous monitoring of two vibration channels.

MONITOR FUNCTIONS OF DUAL VIBRATION MONITOR:

BUFFERED OUTPUT:

The channels A and B coaxial cable connectors on the front panel of the monitor and the terminals on the Signal Input Relay Module provide buffered signals from respective channel transducers. These connectors can be used for connection of external equipment. RECORDER OUTPUT - A recorder output is provided for each channel. Depending on the option selected, the recorder output levels, proportional to full scale, are either 0 to -10 Vdc, +1 to +5 Vdc, or +4 to +20 mA.

Cyclic self-test is performed automatically during monitor operation. Errors encountered during cyclic test disable the monitor and flash an LCD bar graph error code. Should the error be intermittent, the monitor will return to operation, but the error codes are stored for retrieval during user-invoked self-test. Stored error codes are indicated by the OK LEDs flashing at 5 Hz provided that the channel is OK.

WOC maintains the Largest Inventory of Replacement Parts for Bently Nevada Monitoring systems. Additionally, we offer warranty-backed unused and rebuilt boards and board repairs for damaged ones. Our team of professionals is available around the clock for your OEM needs. We at WOC are happy to help you with any automation needs you may have. Please contact our team by phone or email for pricing and availability on any components and repairs.

What is the input signal range for the 3300/20 monitor?

The Bently Nevada 3300/20 Dual Vibration Monitor accepts input signals from proximity probes and velocity sensors. The standard input range for proximity probes is -20V to -2V DC, while for velocity sensors, it varies based on the specific sensor model but typically falls within 0 to 10V AC.

What is the accuracy of the 3300/20 vibration monitor?

The 3300/20 monitor provides high accuracy, with a typical measurement precision of ±1% full-scale range (FSR). This ensures that vibration readings are highly reliable, making it easier to identify developing faults in machinery before they escalate into significant issues.

How does the monitor provide output signals?

The 3300/20 monitor provides both analog and relay outputs. The analog output is available in 4-20 mA or 0-10V DC, which is proportional to the vibration amplitude and can be connected to external monitoring systems.