World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

143729-01 - Cylinder Pressure I/O Module is available in stock which ships the same day.

143729-01 - Cylinder Pressure I/O Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for 143729-01 - Cylinder Pressure I/O Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

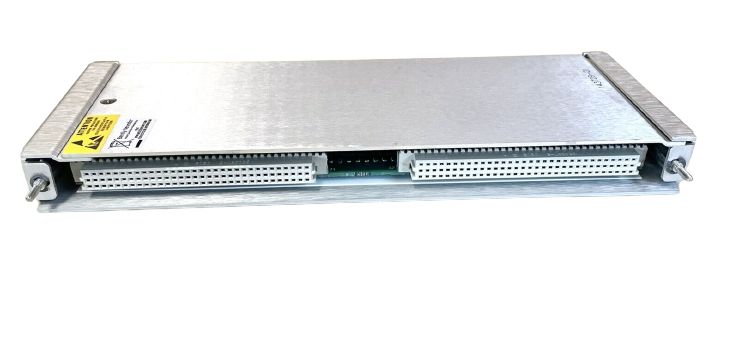

Part Number: 143729-01

Manufacturer: Bently Nevada

Series: 3500/77M

Product Type: Cylinder Pressure I/O Module

Operating temperature: -40 �C to +85 �C

Power Supply Voltage: 125 V dc

Technology: Surface Mount

Board Size: 24.18 cm x 2.44 cm x 24.13 cm

Repair: 3-7 Day

Availability: In Stock

Weight: 0.91 Kg

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

143729-01 is a Cylinder Pressure I/O Module manufactured and designed by Bently Nevada as part of the 3500/77M Series used to control the machinery condition monitoring system. A cylinder pressure I/O module, also known as a cylinder pressure input/output module, is a device used in industrial automation systems to measure and control the pressure of pneumatic or hydraulic cylinders. It is typically part of a larger control system that monitors and regulates various parameters in a manufacturing or industrial process. The cylinder pressure I/O module serves as an interface between the cylinder and the control system, allowing for communication and data exchange. It typically has input channels for measuring cylinder pressure and output channels for controlling the pressure. The input channels of the module are connected to pressure sensors that are installed on the cylinders. These sensors provide real-time feedback on the pressure within the cylinders, allowing the control system to monitor and analyze the performance of the cylinders.

The output channels of the module are connected to control valves or other devices that can regulate the pressure within the cylinders. By sending control signals through these output channels, the module can adjust the pressure to achieve the desired operation of the cylinders. The cylinder pressure I/O module is usually designed to work with standard industrial communication protocols such as Modbus, Profibus, or Ethernet/IP. This enables seamless integration with the overall control system, allowing for easy configuration, monitoring, and control of the cylinder pressure.

FEATURES:

Cylinder pressure I/O modules vary in their specific features and capabilities, but here are some common features you may find in such modules:

Input Channels: Cylinder pressure I/O modules typically have multiple input channels to connect to pressure sensors or transducers. These channels allow for measuring the pressure within the cylinders accurately.

Output Channels: These modules also have output channels that connect to control valves, solenoids, or other devices responsible for regulating the pressure within the cylinders. The output channels enable the module to control the pressure based on the input signals received from the control system.

Communication Protocols: Cylinder pressure I/O modules support various industrial communication protocols, such as Modbus, Profibus, Ethernet/IP, or DeviceNet. These protocols facilitate seamless integration with the control system and enable data exchange between the module and other components of the automation system.

Analog and Digital Inputs/Outputs: The module may provide a combination of analog and digital inputs and outputs. Analog inputs allow for precise measurement of pressure values, while digital inputs and outputs enable discrete control signals and status monitoring.

Signal Conditioning: Cylinder pressure I/O modules often incorporate signal conditioning circuitry to ensure accurate measurement and reliable operation. This may include amplification, filtering, or calibration capabilities to process the signals from pressure sensors effectively.

Diagnostic Functions: Some modules feature built-in diagnostic capabilities to monitor the health and performance of the connected sensors and devices. This can include the detection of sensor faults, communication errors, or abnormal pressure conditions, enabling proactive maintenance and troubleshooting.

Configuration and Monitoring: Cylinder pressure I/O modules typically come with software tools or interfaces that allow for configuration and monitoring. These tools enable users to set channel parameters, calibration values, and alarm thresholds, as well as monitor real-time pressure data and system status.

Mounting and Enclosure Options: These modules may come in various form factors and mounting options, such as DIN rail mounting, panel mounting, or enclosure options for different environmental conditions. This ensures flexibility in integrating the module into different industrial setups.

Scalability and Expandability: Many cylinder pressure I/O modules are designed to be scalable and expandable. This means that multiple modules can be interconnected to increase the number of input and output channels, accommodating the needs of larger automation systems.

WOC has the largest stock of Bently Nevada Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

FREQUENTLY ASKED QUESTIONS:

What types of pressure sensors can be used with a cylinder pressure I/O module?

Cylinder pressure I/O modules are typically compatible with a variety of pressure sensors, including analog or digital sensors. These sensors can measure the pressure of pneumatic or hydraulic cylinders.

What are the common communication protocols supported by cylinder pressure I/O modules?

Popular communication protocols supported by these modules include Modbus, Profibus, Ethernet/IP, and DeviceNet. The specific protocols available depend on the module's manufacturer and model.

What Payment Options Do You Accept?

Bank Transfer is the preferred payment method. For more payment options contact us.